Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Products

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Gear

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft's production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CZPT products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

Our Advantages

1) In-house capability: OEM service as per customers' requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer's requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don't have drawing, what can you do for me?

A: If you don't have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there's any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Material: | 17CrNiMo6 |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

hollow drive shaft

Hollow driveshafts have many benefits. They are light and reduce the overall weight of the vehicle. The largest manufacturer of these components in the world is CZPT. They also offer lightweight solutions for various applications, such as high-performance axles. CZPT driveshafts are manufactured using state-of-the-art technology. They offer excellent quality at competitive prices.

The inner diameter of the hollow shaft reduces the magnitude of the internal forces, thereby reducing the amount of torque transmitted. Unlike solid shafts, hollow shafts are getting stronger. The material inside the hollow shaft is slightly lighter, which further reduces its weight and overall torque. However, this also increases its drag at high speeds. This means that in many applications hollow driveshafts are not as efficient as solid driveshafts.

A conventional hollow drive shaft consists of a first rod 14 and a second rod 14 on both sides. The first rod is connected with the second rod, and the second rod extends in the rotation direction. The two rods are then friction welded to the central area of the hollow shaft. The frictional heat generated during the relative rotation helps to connect the two parts. Hollow drive shafts can be used in internal combustion engines and environmentally-friendly vehicles.

The main advantage of a hollow driveshaft is weight reduction. The splines of the hollow drive shaft can be designed to be smaller than the outside diameter of the hollow shaft, which can significantly reduce weight. Hollow shafts are also less likely to jam compared to solid shafts. Hollow driveshafts are expected to eventually occupy the world market for automotive driveshafts. Its advantages include fuel efficiency and greater flexibility compared to solid prop shafts.

Cardan shaft

Cardan shafts are a popular choice in industrial machinery. They are used to transmit power from one machine to another and are available in a variety of sizes and shapes. They are available in a variety of materials, including steel, copper, and aluminum. If you plan to install one of these shafts, it is important to know the different types of Cardan shafts available. To find the best option, browse the catalog.

Telescopic or "Cardan" prop shafts, also known as U-joints, are ideal for efficient torque transfer between the drive and output system. They are efficient, lightweight, and energy-efficient. They employ advanced methods, including finite element modeling (FEM), to ensure maximum performance, weight, and efficiency. Additionally, the Cardan shaft has an adjustable length for easy repositioning.

Another popular choice for driveshafts is the Cardan shaft, also known as a driveshaft. The purpose of the driveshaft is to transfer torque from the engine to the wheels. They are typically used in high-performance car engines. Some types are made of brass, iron, or steel and have unique surface designs. Cardan shafts are available in inclined and parallel configurations.

Single Cardan shafts are a common replacement for standard Cardan shafts, but if you are looking for dual Cardan shafts for your vehicle, you will want to choose the 1310 series. This type is great for lifted jeeps and requires a CV-compatible transfer case. Some even require axle spacers. The dual Cardan shafts are also designed for lifts, which means it's a good choice for raising and lowering jeeps.

universal joint

Cardan joints are a good choice for drive shafts when operating at a constant speed. Their design allows a constant angular velocity ratio between the input and output shafts. Depending on the application, the recommended speed limit may vary depending on the operating angle, transmission power, and application. These recommendations must be based on pressure. The maximum permissible speed of the drive shaft is determined by determining the angular acceleration.

Because gimbal joints don't require grease, they can last a long time but eventually fail. If they are poorly lubricated or dry, they can cause metal-to-metal contact. The same is true for U-joints that do not have oil filling capability. While they have a long lifespan, it can be difficult to spot warning signs that could indicate impending joint failure. To avoid this, check the drive shaft regularly.

U-joints should not exceed seventy percent of their lateral critical velocity. However, if this speed is exceeded, the part will experience unacceptable vibration, reducing its useful life. To determine the best U-joint for your application, please contact your universal joint supplier. Typically, lower speeds do not require balancing. In these cases, you should consider using a larger pitch diameter to reduce axial force.

To minimize the angular velocity and torque of the output shaft, the two joints must be in phase. Therefore, the output shaft angular displacement does not completely follow the input shaft. Instead, it will lead or lag. Figure 3 illustrates the angular velocity variation and peak displacement lead of the gimbal. The ratios are shown below. The correct torque for this application is 1360 in-Ibs.

Refurbished drive shaft

Refurbished driveshafts are a good choice for a number of reasons. They are cheaper than brand new alternatives and generally just as reliable. Driveshafts are essential to the function of any car, truck, or bus. These parts are made of hollow metal tubes. While this helps reduce weight and expense, it is vulnerable to external influences. If this happens, it may crack or bend. If the shaft suffers this type of damage, it can cause serious damage to the transmission.

A car's driveshaft is a critical component that transmits torque from the engine to the wheels. A1 Drive Shaft is a global supplier of automotive driveshafts and related components. Their factory has the capability to refurbish and repair almost any make or model of driveshafts. Refurbished driveshafts are available for every make and model of vehicle. They can be found on the market for a variety of vehicles, including passenger cars, trucks, vans, and SUVs.

Unusual noises indicate that your driveshaft needs to be replaced. Worn U-joints and bushings can cause excessive vibration. These components cause wear on other parts of the drivetrain. If you notice any of these symptoms, please take your vehicle to the AAMCO Bay Area Center for a thorough inspection. If you suspect damage to the driveshaft, don't wait another minute - it can be very dangerous.

The cost of replacing the drive shaft

The cost of replacing a driveshaft varies, but on average, this repair costs between $200 and $1,500. While this price may vary by vehicle, the cost of parts and labor is generally equal. If you do the repair yourself, you should know how much the parts and labor will cost before you start work. Some parts can be more expensive than others, so it's a good idea to compare the cost of several locations before deciding where to go.

If you notice any of these symptoms, you should seek a repair shop immediately. If you are still not sure if the driveshaft is damaged, do not drive the car any distance until it is repaired. Symptoms to look for include lack of power, difficulty moving the car, squeaking, clanking, or vibrating when the vehicle is moving.

Parts used in drive shafts include center support bearings, slip joints, and U-joints. The price of the driveshaft varies by vehicle and may vary by model of the same year. Also, different types of driveshafts require different repair methods and are much more expensive. Overall, though, a driveshaft replacement costs between $300 and $1,300. The process may take about an hour, depending on the vehicle model.

Several factors can lead to the need to replace the drive shaft, including bearing corrosion, damaged seals, or other components. In some cases, the U-joint indicates that the drive shaft needs to be replaced. Even if the bearings and u-joints are in good condition, they will eventually break and require the replacement of the drive shaft. However, these parts are not cheap, and if a damaged driveshaft is a symptom of a bigger problem, you should take the time to replace the shaft.

editor by CX 2023-05-18

China OEM gear reducer motor gearbox reducer high quality gearbox ev reductor gear box 90 degree shaft gear reducer qm gearbox k helical b with Good quality

parallel shaft gearmotor helical inline gearmotor motoreductor gearmotor reductor gear reducer with reducer backstop

F series gear reducer is 1 kind of parallel shaft helical gear reducer , which consist of 2 or 3 stageshelical gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,theprocess of carburizing and quenching, grinding ,which give it follow characters :Stable transmission ,low noiseand temperature ,high loading ,long working lift . Wide application ,specialize in Metallurgy ,Sewage treatment,Chemical Industry , Pharmacy ,Agriculture equipment and Oil industry

Specifications:1) Output speed: 0.6~1,571r/min2) Output torque: up to 21700N.m3) Motor power: 0.12~200kW4) Mounted form: foot-mounted and flange-mounted mounting

Product NameSLK Series Rigid Tooth helical bevel reducer Gear Material20CrMnTi Case MaterialHT250Shaft Material 20CrMnTiGear ProcessingGrinding finish by HOFLER Grinding MachinesColor CustomizedNoise Test65~70dBEfficiency94%~98% (depends on the transmission stage) Lubricating oilShell Omala synthetic oil or mineral oil , or similar brand Heat treatmenttempering, cementiting, quenching,etc.Brand of bearingsC&U bearing, ZWZ,LYC, HRB, SKF,NSK and so onBrand of oil sealNAK or other brandTemp. rise (MAX)40 °Temp. rise (Oil)(MAX)50 °Vibration≤20µ Original Advance mb170 marine gearbox in China m

Certifications

Packaging & Shipping

Packing Details: Standard carton/Pallet/Standard wooden case

Delivery Details : 7-20 working days upon payment

Company InformationAbout us

Established in 1985, CZPT TRANSMISSION MACHINERY CO., LTD is a high and new technology enterprise engaging in research, develop and manufacture for reducer & speed variator, 1 of the director member of China Reducer Association of China General Machinery.

It covers more than 40,000 square meters, has more than 400 staff , 20% of whom are technicians, equipped with more than 300 sets the most advanced accurate numerical control equipment, including German HOFLER forming gear grinding machine to improve quality.

set up more than 30 national sales branches to serve our customers in time and thoroughly.

Our products also exported to more than 30 countries main in Europe, Asia America, and Africa, with high reputation.

Trade Shows

Related Product

Main product list: 16 series including SLR/SLS/SLK/SLF series hard tooth flank gear reducer , SLRC series aluminium case helical gear reducers,SLHSLB series high power speed reducer, SLP series planetary speed reducer, X/B series cycloidal reducer, SLXG series shaft-mounted gear box, SLSWL series worm screw jack, SLT series helical cone gear box, altogether more than 10,000 ratios, various specification make us at the head of domestic transmission industry, widely serve the mechanical transmission field of light & heavy industry such as: beer & High precision high torque CZPT RV-E cycloidal gearbox reducer for robot joints beverage, mining machine, food packing, textile printing, rubber & plastic material, petrochemical industry, jack-up transportation, pharmacy & process hides, environmental protection equipment.

FAQ1.Payment Term: TT, L/C

2.Delivery time: about 30 days from receive payment.

3.We accept customized products as per your special requirement.

4.Xihu (West Lake) Dis.lines for the Selection:Usually we can select 1 machine which is suitable for you with some informations from you,such as ratio/motor speed/mounting dimension/ out torque etc.

5.If the minimum order amount is in excess of $10000, there are preferential.

Q1: What information should I tell you to confirm the product?

A:Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I don't know which 1 I need?

A:Dont worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q3: What is your product warranty period?

A:We offer 1 year warranty since the vessel departure date left China.

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q7: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, Heavy duty V belt pulley sheaves machine V pulley mining machinery pulleys pls feel free to contact us as below:

Contact us

How to Choose the Right Worm Shaft

You might be curious to know how to choose the right Worm Shaft. In this article, you will learn about worm modules with the same pitch diameter, Double-thread worm gears, and Self-locking worm drive. Once you have chosen the proper Worm Shaft, you will find it easier to use the equipment in your home. There are many advantages to selecting the right Worm Shaft. Read on to learn more.

Concave shape

The concave shape of a worm's shaft is an important characteristic for the design of a worm gearing. Worm gearings can be found in a wide range of shapes, and the basic profile parameters are available in professional and firm literature. These parameters are used in geometry calculations, and a selection of the right worm gearing for a particular application can be based on these requirements.

The thread profile of a worm is defined by the tangent to the axis of its main cylinder. The teeth are shaped in a straight line with a slightly concave shape along the sides. It resembles a helical gear, and the profile of the worm itself is straight. This type of gearing is often used when the number of teeth is greater than a certain limit.

The geometry of a worm gear depends on the type and manufacturer. In the earliest days, worms were made similar to simple screw threads, and could be chased on a lathe. During this time, the worm was often made with straight-sided tools to produce threads in the acme plane. Later, grinding techniques improved the thread finish and reduced distortions resulting from hardening.

When a worm gearing has multiple teeth, the pitch angle is a key parameter. A greater pitch angle increases efficiency. If you want to increase the pitch angle without increasing the number of teeth, you can replace a worm pair with a different number of thread starts. The helix angle must increase while the center distance remains constant. A higher pitch angle, however, is almost never used for power transmissions.

The minimum number of gear teeth depends on the angle of pressure at zero gearing correction. The diameter of the worm is d1, and is based on a known module value, mx or mn. Generally, larger values of m are assigned to larger modules. And a smaller number of teeth is called a low pitch angle. In case of a low pitch angle, spiral gearing is used. The pitch angle of the worm gear is smaller than 10 degrees.

Multiple-thread worms

Multi-thread worms can be divided into sets of one, two, or four threads. The ratio is determined by the number of threads on each set and the number of teeth on the apparatus. The most common worm thread counts are 1,2,4, and 6. To find out how many threads you have, count the start and end of each thread and divide by two. Using this method, you will get the correct thread count every time.

The tangent plane of a worm's pitch profile changes as the worm moves lengthwise along the thread. The lead angle is greatest at the throat, and decreases on both sides. The curvature radius r" varies proportionally with the worm's radius, or pitch angle at the considered point. Hence, the worm leads angle, r, is increased with decreased inclination and decreases with increasing inclination.

Multi-thread worms are characterized by a constant leverage between the gear surface and the worm threads. The ratio of worm-tooth surfaces to the worm's length varies, which enables the wormgear to be adjusted in the same direction. To optimize the gear contact between the worm and gear, the tangent relationship between the two surfaces is optimal.

The efficiency of worm gear drives is largely dependent on the helix angle of the worm. Multiple thread worms can improve the efficiency of the worm gear drive by as much as 25 to 50% compared to single-thread worms. Worm gears are made of bronze, which reduces friction and heat on the worm's teeth. A specialized machine can cut the worm gears for maximum efficiency.

Double-thread worm gears

In many different applications, worm gears are used to drive a worm wheel. These gears are unique in that the worm cannot be reversed by the power applied to the worm wheel. Because of their self-locking properties, they can be used to prevent reversing motion, although this is not a dependable function. Applications for worm gears include hoisting equipment, elevators, chain blocks, fishing reels, and automotive power steering. Because of their compact size, these gears are often used in applications with limited space.

Worm sets typically exhibit more wear than other types of gears, and this means that they require more limited contact patterns in new parts. Worm wheel teeth are concave, making it difficult to measure tooth thickness with pins, balls, and gear tooth calipers. To measure tooth thickness, however, you can measure backlash, a measurement of the spacing between teeth in a gear. Backlash can vary from one worm gear to another, so it is important to check the backlash at several points. If the backlash is different in two places, this indicates that the teeth may have different spacing.

Single-thread worm gears provide high speed reduction but lower efficiency. A multi-thread worm gear can provide high efficiency and high speed, but this comes with a trade-off in terms of horsepower. However, there are many other applications for worm gears. In addition to heavy-duty applications, they are often used in light-duty gearboxes for a variety of functions. When used in conjunction with double-thread worms, they allow for a substantial speed reduction in one step.

Stainless-steel worm gears can be used in damp environments. The worm gear is not susceptible to rust and is ideal for wet and damp environments. The worm wheel's smooth surfaces make cleaning them easy. However, they do require lubricants. The most common lubricant for worm gears is mineral oil. This lubricant is designed to protect the worm drive.

Self-locking worm drive

A self-locking worm drive prevents the platform from moving backward when the motor stops. A dynamic self-locking worm drive is also possible but does not include a holding brake. This type of self-locking worm drive is not susceptible to vibrations, but may rattle if released. In addition, it may require an additional brake to keep the platform from moving. A positive brake may be necessary for safety.

A self-locking worm drive does not allow for the interchangeability of the driven and driving gears. This is unlike spur gear trains that allow both to interchange positions. In a self-locking worm drive, the driving gear is always engaged and the driven gear remains stationary. The drive mechanism locks automatically when the worm is operated in the wrong manner. Several sources of information on self-locking worm gears include the Machinery's Handbook.

A self-locking worm drive is not difficult to build and has a great mechanical advantage. In fact, the output of a self-locking worm drive cannot be backdriven by the input shaft. DIYers can build a self-locking worm drive by modifying threaded rods and off-the-shelf gears. However, it is easier to make a ratchet and pawl mechanism, and is significantly less expensive. However, it is important to understand that you can only drive one worm at a time.

Another advantage of a self-locking worm drive is the fact that it is not possible to interchange the input and output shafts. This is a major benefit of using such a mechanism, as you can achieve high gear reduction without increasing the size of the gear box. If you're thinking about buying a self-locking worm gear for a specific application, consider the following tips to make the right choice.

An enveloping worm gear set is best for applications requiring high accuracy and efficiency, and minimum backlash. Its teeth are shaped differently, and the worm's threads are modified to increase surface contact. They are more expensive to manufacture than their single-start counterparts, but this type is best for applications where accuracy is crucial. The worm drive is also a great option for heavy trucks because of their large size and high-torque capacity.

Best manufacturer made in China - replacement parts - PTO shaft manufacturer & factory Hydraulic constant velocity joint for pto shaft Tractor Pto Gearbox to Suit Group 2 Pump with ce certificate top quality low price

We - EPG Group the most significant agricultural gearbox and pto factory in China with 5 diverse branches. For far more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

generate shaft with keyway 2007 toyota tacoma push shaft yoke EPG rear travel shaft consistent velocity joint is pto shaft for bush hog tractor provide specialised pto shaft locking pin in pto shaft go over ebay design and style, 2002 ford ranger push shaft maker nissan rogue push shaft and pto shaft companies in ludhiana revenue crown vic driveshaft of agricultural equipment and farm implements, which has an unbiased import and export legal rights. "EPG" model rotocultivator ploughshares in T.S. overall lines developed in our manufacturing unit have been analyzed and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People's Republic of China.

Hydraulic Tractor PTO Gearbox to Fit Group 2 pump

The Gearboxes are developed for connecting gear pumps to farm tractor power take offs (PTO).Output pace of electricity consider offs is 540rpm which can be compared with the suitable operating speeds of hydraulic pumps.Various enter running speeds can also be ideal,provided that the PTO gearbox output pace does not exceed 3000 rpm.

Gears

Produced in Steel UNI 18 PCR M03.Stub enamel ensure really large resistance and run very quietly.

Shafts

Made in steel UNI 16 CRN4.They are coupled with splined gears and are created to stand the torque values stated in the catalogue.

Lubrication

SAE 90 equipment oil should be set in the pto gearbox prior to use, alter the oil right after the 1st sixty-80 hours and then each and every 12 months or 1500 hrs which ever fal EPT initial.

Upkeep

Make sure you verify the oil degree by means of the EPT oil window every single fifty hrs.Operating temperatures ought to not exceed 120 degrees celcius underneath continuos duty cycle.

Packaging & Shipping

Plastic bag packing for 1 piece / two items in one exporting carton / 100 cartons set on a pallet

FAQ

1.Q:Is your organization a trading company or a manufacturer?

A:Our business is a trading firm also a manufacturer, we have our very own factory to create gearbox, pump assistance..And so forth

Also we distribute gear pumps, tractor machinery,dump truck pump from chosen premium suppliers to meet up with customers' variable demand.

2.Q:What about the high quality management and guarantee ?

A:"High quality first, Customers foremost".Each and every piece of items is cheeked and examined strictly one particular by a single ahead of packing and shipping.

Our merchandise have one particular 12 months warranty, technical assist is unlimited from us.

3.Q:Can you supply samples for checking and tests?

A:Indeed,we offer free of charge samples for examining the construct top quality and real functionality of our merchandise,the freight want to be coverd by consumer.

four.Q:How can I get to your company?

A:Our organization address is No.888 Huaxu Highway,Xihu (West Lake) Dis. district,ZheJiang ,China

It is about thirty minutes by car from ZheJiang Xihu (West Lake) Dis.ao airport or ZheJiang Xihu (West Lake) Dis.ao Railway station.

China manufacturer & factory supplier for VF in Port Harcourt Nigeria series worm gearbox small worm gearbox With high quality best price & service

With in excess of thirty many years of combined expertise in Bearings and Power Transmission, EPG is entirely able of developing and making products to in shape your certain software. Our experienced personnel of engineers and customer service associates look forward to delivering you with anyIf you are fascinated in any of our products or would like to examine a likely get, remember to feel free of charge to speak to us.

Overview

Fast Particulars

- Relevant Industries:

-

Constructing Materials Shops, Production Plant, Equipment Restore Stores, Farms, Development works , Foodstuff & Beverage Outlets

- Item name:

-

Worm Equipment Reducer

- Shade:

-

Blue,Grey,Or Customized

- Guarantee:

-

1 Year

- Application:

-

Meals ,Plastic, Convery, Machinery, Feed, Mining and so on

The computer then compares the output subassembly stack height to the distance amongst the housing bearing seats and calculates the shim pack necessary for the wanted bearing endplay. Making use of the worm-equipment centerline measurement, it displays assemblers how to distribute shims among the entrance and rear bearings to exactly centre the equipment in the housing. Measurement accuracy is ±0.001 in. Total cycle time, excluding loading and unloading, is much less than twenty sec.

- Certification:

-

ISO9001 , CE

- Mounting Situation:

-

Horizontal (Shaft Mounted, Flange Mounted)

- Packing:

-

Picket Box

- Bearing:

-

C&U, NAK, NSK,SKF

- OEM support:

-

Offered

Offer Potential

- Offer Capacity:

- one thousand Piece/Items for each Month

Packaging & Supply

EPG MachinerPTO shaft connectors on tractors are not standardized which can lead to difficulties when connecting the PTO shaft. For example, some more mature tractor types have the connection flange closer to the tractor alone generating it challenging to connect and guide to a potential security hazard.y is found in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou worldwide airport.

- Packaging Specifics

- Plywood circumstance

- Port

- Ningbo,Shanghai

-

Direct Time

: -

Amount(Containers) one - 10 >10 Est. Time(days) fifteen To be negotiated

On the web Customization

Attributes:

Substantial modular design and style, biomimetic surface with owned intellectual home appropriate.

Undertake German worm hob to approach the worm wheel.

With the specific gear geometry, it will get high torque, effectiveness and extended existence circle.

It can obtain the direct mix for two sets of gearbox.

Mounting method: foot mounted, flange mounted, torque arm mounted.

Output shaft: solid shaft, hollow shaft.

Designs:

Hollow Shaft Enter with IEC-normalized Motor Flange

VF030~VF105

Solid Shaft Enter

VF030~VF105

Attributes:

one. High quality aluminum alloy equipment box, gentle excess weight and not rust

2. 2 optional worm wheel supplies: Tin bronze or aluminum bronze alloy

3. Regular parts and really versatile for shaft configurations and motor flange interface

four. Numerous optional mounting options

5. Minimal sound, Substantial efficiency in heat dissipation

Ratio: 5, 7.5, 10, fifteen, twenty, twenty five, 30, forty, 50, sixty, 90, one hundred and five

Installation:

Flange Mounted

Foot Mounted

Torque Arm Mounted

Lubrication:

Grease Lubrication

Oil-bathtub and Splash Lubrication

Cooling:

All-natural Cooling

Q: Are you trading business or company ?

Q: Are you trading business or company ?

A: We At any time-Power Team one of the biggest transmission suppliers in the entire world are manufacturing facility.

Q: How extended is your shipping and delivery time?

A: Generally it is 5-10 days if the goods are in inventory. or it is 15-20 times if the products are not in stock.

Q: Can we purchase 1 pc of each merchandise for high quality screening?

A: Of course, we are happy to accept demo order for top quality testing.

Q: What is your conditions of payment ?

A: Payment=1000USD, thirty% T/T in advance, balance just before shippment.

If you have other concern, freely to speak to us,you should.

China manufacturer & factory supplier for china in Malang Indonesia supplier ZDY ZLY ZSY type helical bevel gear reducer construction lifting hoist gearbox With high quality best price & service

No other assortment of chains can beat EPG for variety. In addition to traditional roller chains of all varieties and dimensions, roller chains with attachments and double pitch roller chains, we also supply particular chains this sort of as grip chains, accumulation chains, elastomeric profile chains, leaf chains, bushed conveyor chains, hollow pin chains and a lot of other models. Upkeep-free or corrosion-evidence chains are available for particular applications. Our pin oven chains and tube conveyor chains empower a wide range of remedies for the effective manufacturing and optimum conveying of cans and tubes. Uncover out far more about our productEPG has established up a complete established of quality management technique which is provided with advanced inspection and test gear.

Overview

Rapid Specifics

- Applicable Industries:

-

Producing Plant

- Product Quantity:

-

ZLY one hundred sixty 355 four hundred 450 five hundred

- Rated Power:

-

one.5~6229KW (tailored)

- Pole:

-

Single Two A few Stage Pace Reducer

- Ratio:

-

one.25-a hundred

- Housing Material:

-

Forged Iron

- Working temperature:

-

-forty~45℃

- Software:

-

for agricultural machinery mining, chemical market,metal ,lifting

- Method:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Situation:

-

Horizontal,Vertical,Flange

Offer Ability

- Supply Ability:

- 500 Set/Sets for every Month type helical bevel equipment development lifting hoist gearbox

Girard DYN assortment-2 Our range of worm gearboxes is especially suited to demanding stepper and servo motor apps.

Packaging & Shipping and delivery

- Packaging Details

- sea worthy wooden scenario for ZDY/ZLY/ZSY/ ZFY type helical bevel equipment building lifting hoist gearbox

- Port

- Qingdao Shanghai Ningbo Tianjin

On the internet Customization

Solution Description

YOUR Expert MANUFACTURE

—— Considering that 1995

Z Series Helical Gear Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical equipment reducer

D (DBY and DCY) series hard tooth surface cone gear reducer

Chinese speed reducer is commonly used in mining machinery, chemical industry,steel metallurgy, mild market,environmental safety, paper making, printing, lifting transportation, food market and so on.

Principal Series Product: R series helical gear reducer, K sequence spiral bevel equipment reducer, NGW, P series planetary reducer, H B collection gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, and so forth. Meanwhile, map sample processing business can be carried out.

Feature:

-

Relevant to the metallurgical,power technology,water remedy,design,chemical,paper,

textiles,medication,foodstuff and other industries.

-

The transmission effectiveness of one-stage can attain up to ninety eight%, two-stage can reach 96%, three-phase can attain ninety four%.

-

The equipment processed by Carburizing & Grinding with higher precision.

-

Large precision gear, constant transmission, massive load potential

-

Prolonged support lifestyle.

- One Two 3 Stage Speed Reducer

Specification

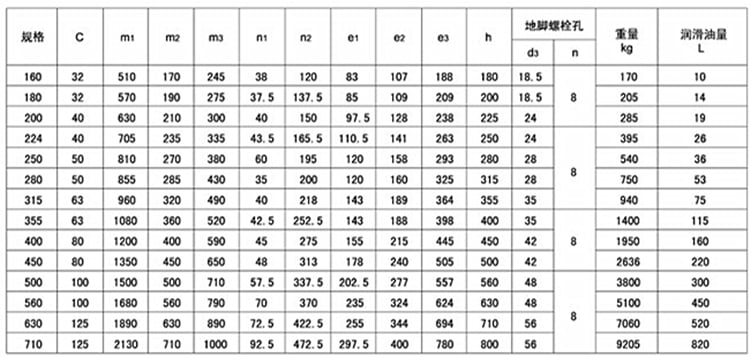

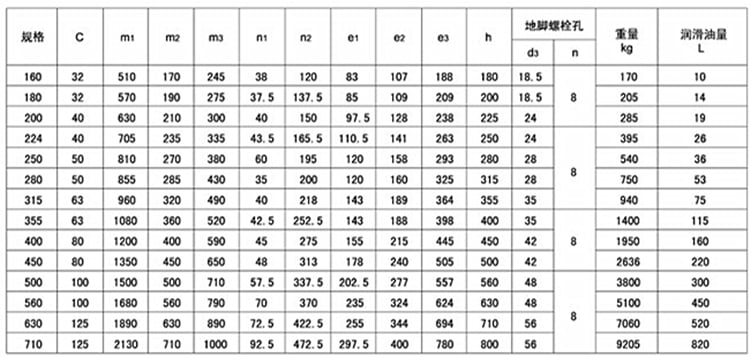

ZDY/ZLY/ZSY/ ZFY sort helical bevel gear construction lifting hoist gearbox:

(you should get in touch with us for much more varieties & product)

| Driven equipment | |||

| Squander drinking water therapy | Thickeners,filter presses,flocculation apparata,aerators,raking gear,mixed longitudinal and rotary rakes,pre-thickeners,screw pumps,h2o turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping gadgets, carterpillar travelling gears, bucket wheel excavators as decide up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical inClose up of two yokes with the common joint. Be aware the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft area --Travel (outer) yoke has a female (common spline) gap and “Y” form conclude that is the universal joint (UJ) mount. --UJ is a cross shaped casting having roller bearings enclosed with caps at all four points and is held into the yoke with 4 “C” clips --Interior yoke and drive shaft is yet another yoke welded to the push conclude, of the travel shaft. --Driven shaft and inner yoke is the driven shaft that rides within of the drive shaft and has a yoke welded at the pushed stop --UJ another UJ as abovedustry | Plate bending equipment, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metallic doing work mills | plate tilters, ingot pushers, winding devices, cooling bed transfer frames, roller straigheners, desk ongoing intermittent, roller tables reversing tube mills, shears steady, casting motorists, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, excellent lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower followers, blowers axial and radial |

| Cane sugar generation | Cane knives, cane mills | Beet sugar manufacturing | Beet cossettes macerators, extraction crops, mechanical fridges, juice boilers, sugar beet washing equipment, sugar beet cutter |

| Paper devices | Pulper drives | Cableways | Materials ropeways, continuous ropeway |

| Cement sector | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Product assortment:

Closely making use of the best reduction ratio.

Reduction ratio = servo motor velocity / reducer output shaft pace

Torque calculation: Torque calculation is extremely crucial for the life of reducer, and spend focus to whether or not the optimum torque benefit (TP) of acceleration exceeds the greatest load torque of the reducer.

The applicable power is typically the applicable power of the servo models on the market, the applicability of the reducer is very large, the working coefficient can be taken care of earlier mentioned 1.2, but the choice can also be based on their personal wants to determine.ZSY collection two stage cylindrical transmission reducer for belt conveyor.ZLY collection 2 phase helical pace reducer for paper mill.1 10 ratio gearbox pace reducer for plastic extruder device.ZLY Rubber Extruder Mini Electric Motor Gear Pace Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor. ZDY/ZLY/ZSY/ ZFY kind helical bevel equipment construction lifting hoist gearbox.

Technological innovation

Chinese Electric powered Motor Gear Pace Reducer is a mechanical transmission in many fields of the national economic climate. The solution categories protected by the industry consist of all kinds of equipment reducer, planetary gear reducer and worm gearbox, as effectively as different unique transmission units these kinds of as velocity escalating system, velocity manage Units, including numerous sorts of versatile transmission units, this sort of as compound transmission. Items and solutions in the field of metallurgy, nonferrous metals, coal, creating materials, ships, h2o conservancy, electricity, building equipment and petrochemical industries.

In all fields of national financial system and national protection sector, gearbox items have a broad variety of purposes. Food light business, electric powered equipment, building equipment, metallurgy machinery, cement machinery, environmental safety equipment, digital appliances, road construction equipment, water conservancy machinery, chemical equipment, mining equipment, conveyor equipment, creating components equipment, rubber equipment, petroleum equipment and other industries have robust demand of Reducer products.ZSY collection two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 phase helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder equipment.ZLY Rubber Extruder Mini Electrical Motor Gear Pace Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor. ZDY/ZLY/ZSY/ ZFY sort helical bevel equipment construction lifting hoist gearbox.

Packaging & Delivery

Firm Details

Started in 1995, HangZhou Ever-Energy Power machinery Co.,Ltd has 22 many years of reducer production encounter and reliability. The firm has professional engineer crew, superior technologies generation and expert personnel, with located in HangZhou of ZheJiang province which has reliable industrial base and designed transportation.

FAQ

1.Q:Are you the manufacturing unit or trading business?

A:We are the specialist Manufacturing unit with 22 many years of encounter.

2.Q:Can you customize in accordance to our specifications?

A:Of course, we can style nonstandard goods in accordance to customer's drawing and sample.

3.Q:How long is the delivery day?

A:10-twenty functioning times.

4.Q:Exactly where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get listed here by substantial speed prepare or fly to JinIt is our aim to supply a vast assortment of top quality products at reasonably priced costs, give the greatest services for customers satisfied and lead to our continued advancement. an.

Welcome to visit us!

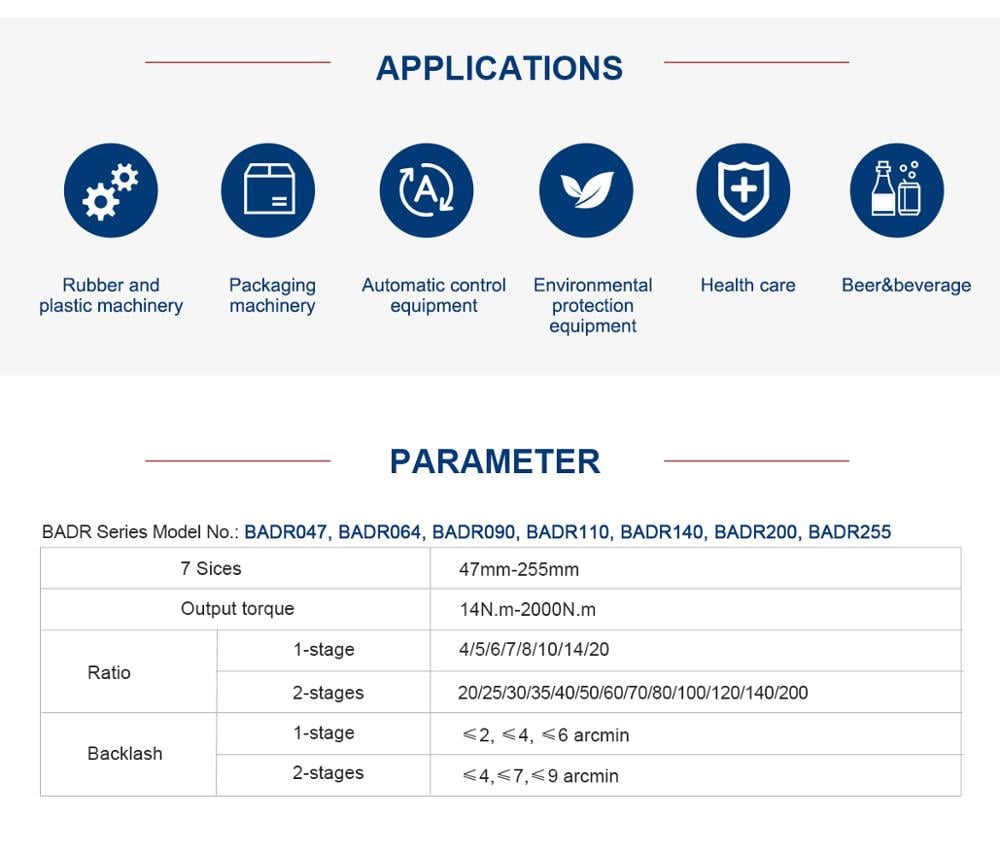

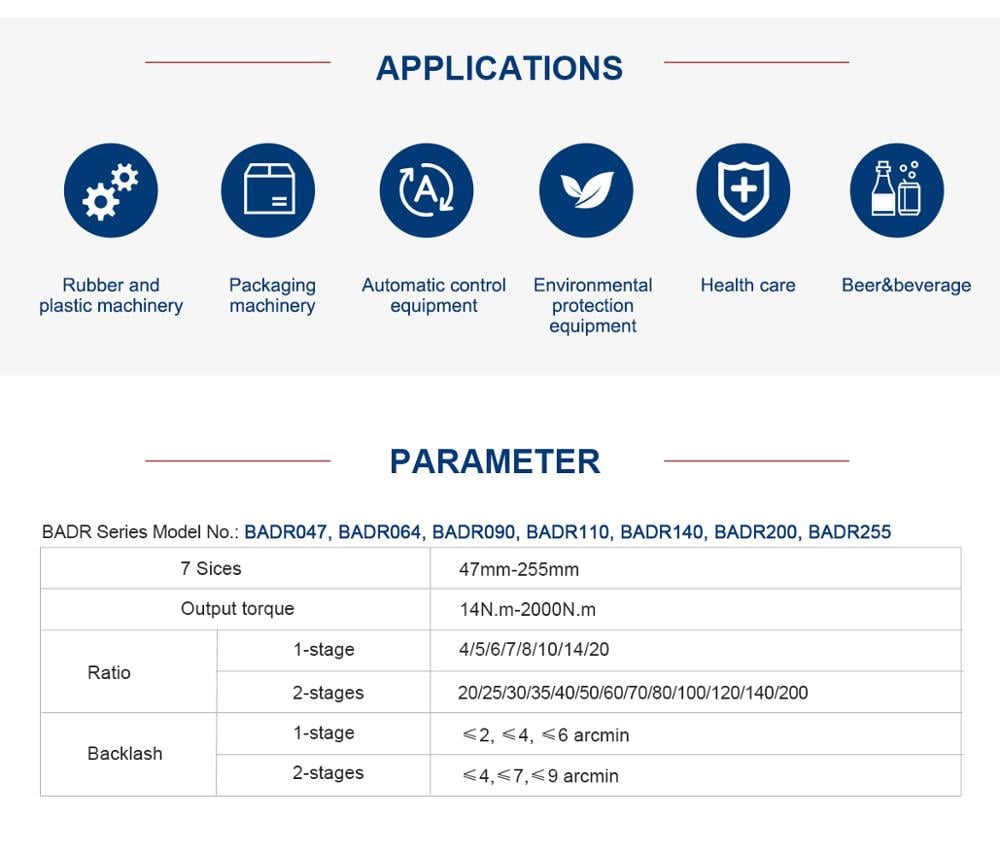

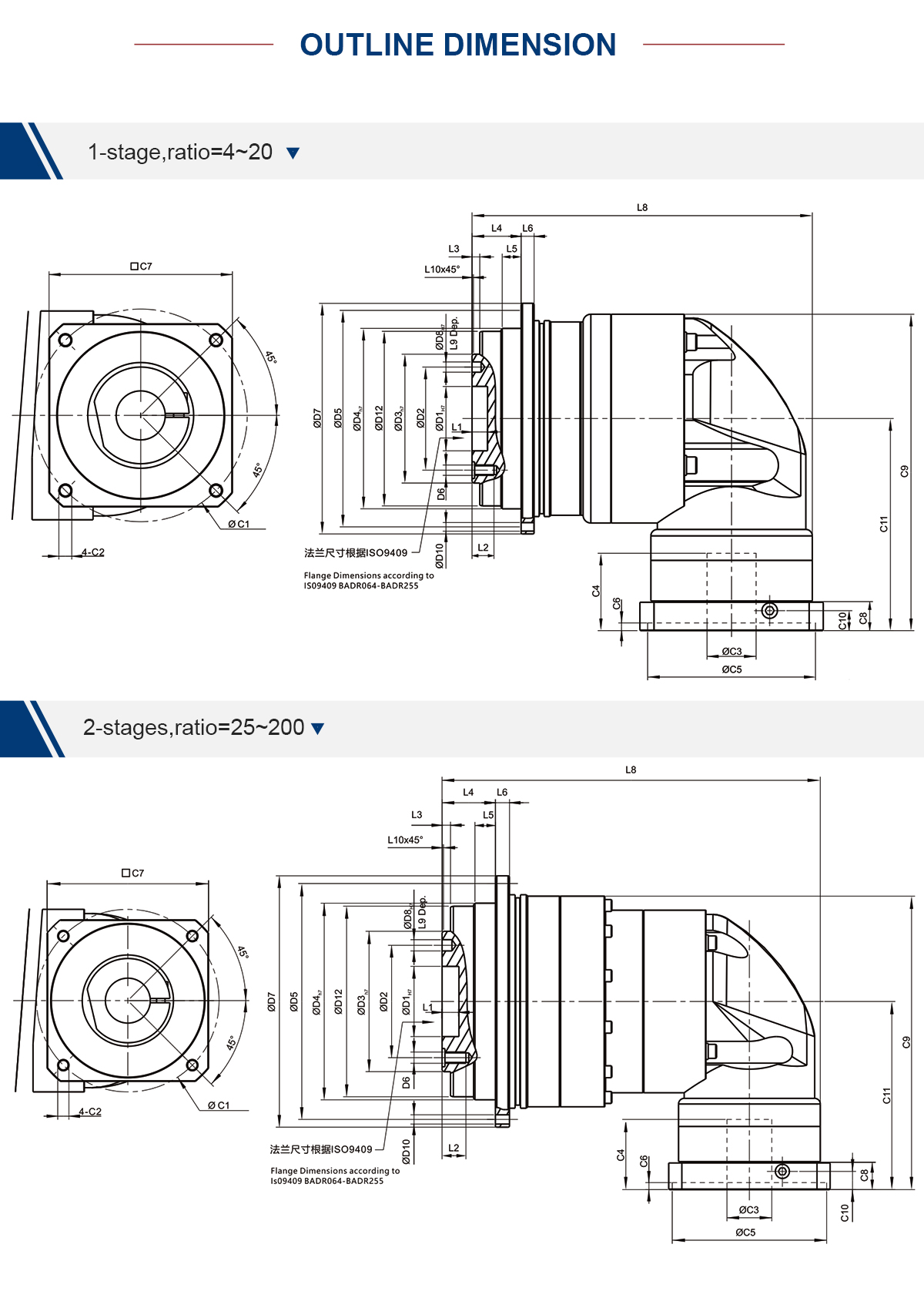

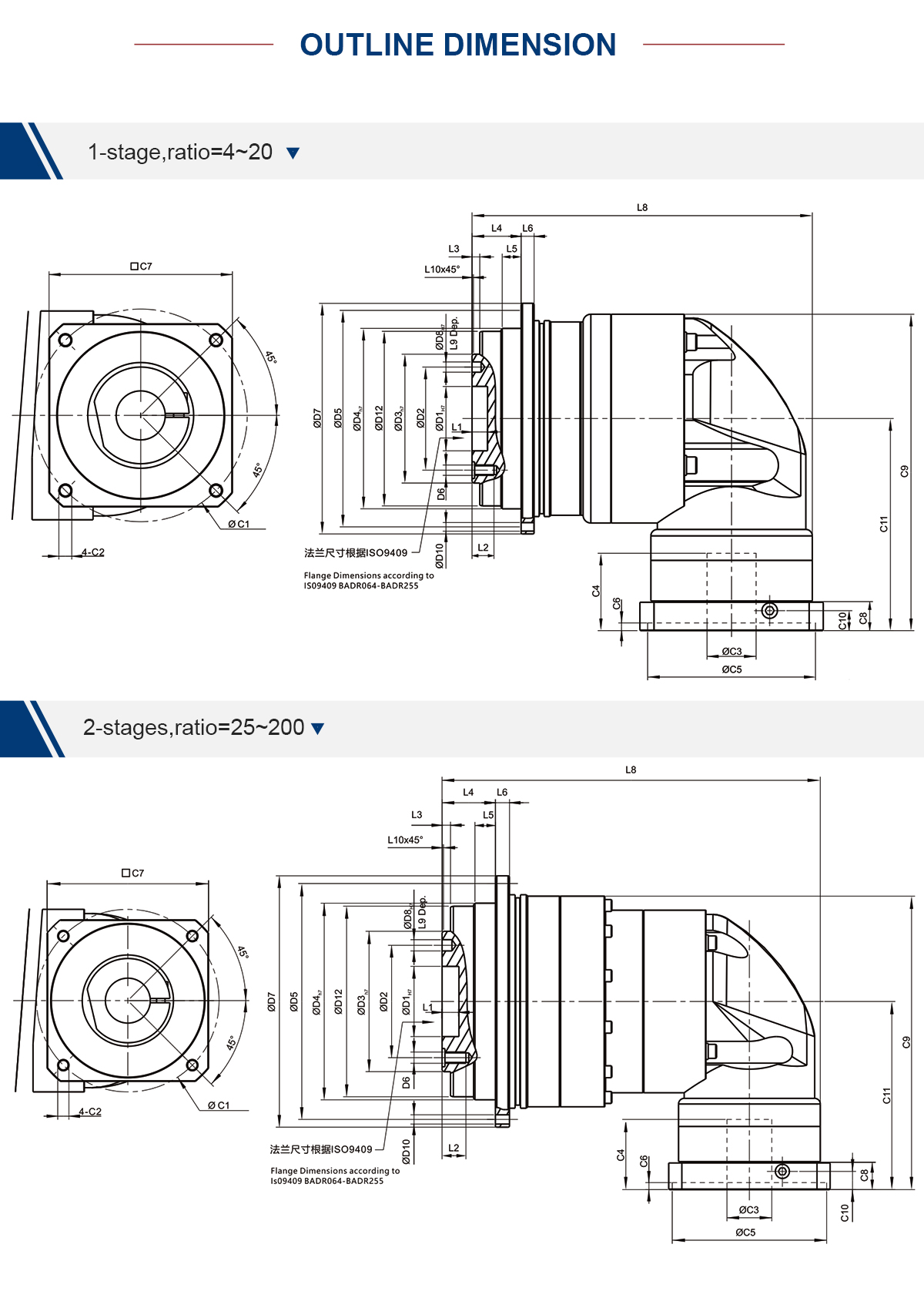

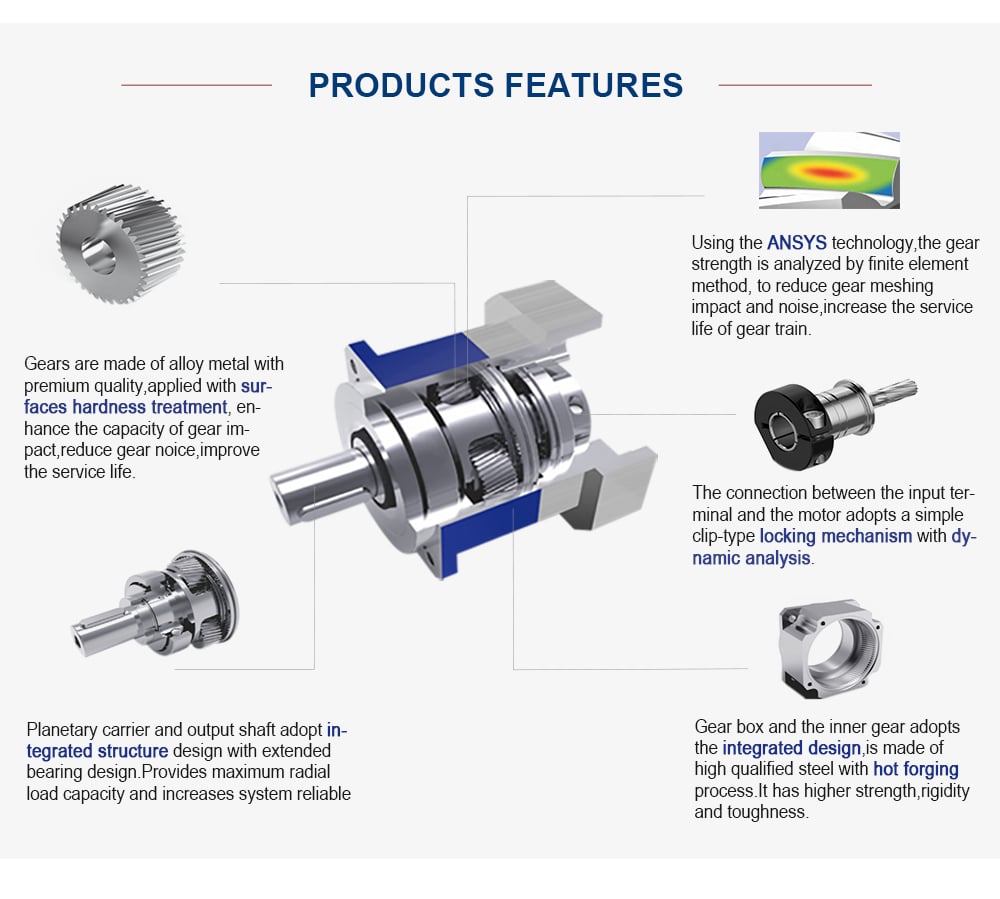

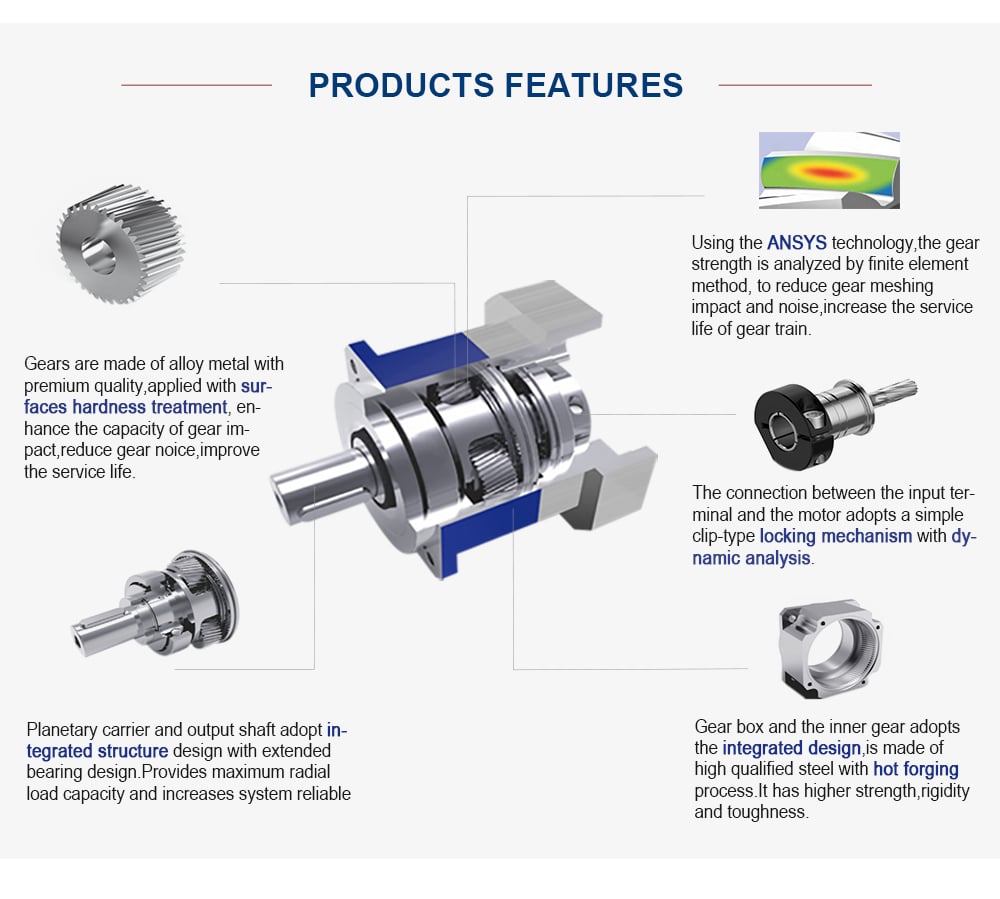

Best China manufacturer & factory china in Al-Mansurah Egypt manufacturer BADR255 high toique compact precise right angle planetary speed gearbox With high quality best price

We will provide best services and high quality products with all sincerity. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes....

Overview

Quick Details

- Applicable Industries:

-

CNC

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

The PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor.

1500~2000 N.m

- Input Speed:

-

2000rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

planetary 90 degree gearbox

- Material:

-

20CrMnTi, 40Cr

- Ratio:

-

4~200

- Backlash:

-

P1/P2

- Ingress protection:

-

IP65

- Color:

-

champagne gold+black/ silver+blue/ OEM color

- Heat treatment:

-

hot forged/hardening

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

TECHNOLOGY LEADER IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for over 30 years now. This great determination has helped us become an undisputed global technology and quality leader.

-

Lead Time

: -

Quantity(Pieces) 1 - 1000 >1000 Est. Time(days) 30 To be negotiated

Online Customization

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAUMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.LIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced management software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And - 100% inspect finished spare parts before put in storage. - 100% inspect before assembly. - 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

Best China manufacturer & factory manufacturer in Thrissur India of New style fashion high precision helical gear worm gear reducer commutator good efficiency gearbox With high quality best price

Our producA power take-off or power takeoff (PTO) is any of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine.ts are applied in many fields.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product name:

-

Gear reducer

- Color:

-

Customer Requirement

- Packing:

-

PLYWOOD

- Certification:

-

ISO9001

- Material:

-

Cast Iron

- MOQ:

-

1 PC

- Output Form:

-

Flange Output

- Warranty:

-

12 Months

- Mounting Position:

-

Horizontal (foot Mounted)

Supply Ability

- Supply Ability:

- 1111 Bag/Bags per Day

Packaging & Delivery

- Packaging Details

- PLYWOOD

- Port

- nb

-

Lead Time

: -

Quantity(Bags) 1 - 10 11 - 50 >50 Est. Time(days) 15 30 To be negotiated

Online Customization

Product Description

| Product features |

| 1. R series helical gearmotor own rational design, compact construction, smaller size than X or B series cycloidal gearmotor at the same permitted torque. |

| 2. Little vibration and low noise, with high transmission efficiency. |

| 3. The material of gears is 20CrMnTi alloy steel and the hardness can reach to HRC58°~ 62° after tempering,cementiting, quenching etc. heat treatment. All the gears are processed by accurate grinding and the precision can reach to grade 6~5. |

| 4. The products have been mainly used in chemical machinery, cement agitator machinery, printing and packaging machinery, mine and power transmission machinery,metallurgy etc. |

| Application:R series reducer is a kind of gear is used to reduce the motor speed and improve the output torque of the principle of speed reducer. It uses the gear and gear meshing, with advanced design and novel structure of retarding mechanism.It has been widely used in metallurgy, mining, petroleum, chemical industry, ship, light industry, food, textile, printing and dyeing. |

| General Technical data | |

| Housing material | HT250 high strength casting lron |

| Housing hardness | HBS190-240 |

| Gear material | 20CrMn Ti alloy steel |

| Surface hardness of gears | HRC58°~62° |

| Gear core hardness | HRC33~40 |

| Input/output shaft material | 40CrMo alloy steel |

| Input/output shaft hardness | HRC25In one way or another, all breathers let air flow between the inside and outside of the gear reducer as the unit warms during startup and cools after shutdown. If the breather is completely shielded from lubricant splash inside the reducer, almost any design will be effective. Unfortunately, this is usually not the case, particularly since most gear reducer housings can mount in a variety of positions. If the breather is exposed to oil splash, a bubble of oil typically forms across the breather's inside orifice, and escaping warm air carries it to the outside. Over time, these small droplets accumulate until the unit is visibly “leaking.”~30 |

| Machining precision of gears | accurate grinding,6~7 Grade |

| Lubricant oil | GB L-CKC220-460,Shell Omala220-460 |

| Heat treatment | Tempering,Cementiting,Quenching,etc |

| Efficiency | 94%~96% (depends on the transmission stage) |

| Noise (MAX) | 60~68dB |

| Temp.rise (MAX) | 40℃ |

| Temp.rise (Oi) (MAX) | 50℃ |

| Vibration | ≤20μm |

| Backlash | ≤20Arcmin |

| Brand of bearings | China Top brand HRB,LYC,ZWZ or other brands requested,NSK..... |

| Brand of oil seal | NAK--- Taiwan or other brands requested |

Company Information

Packaging & Shipping

FAQ

Q1: Wonder if you accept small orders?

A1: Do not worry. Feel free to contact us .in order to get more orders and give our clients more convener ,we accept small order.

Q2: Can you send products to my country?

A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?

A3: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q4: What's your payment terms ?

A4: By T/T,LC AT SIGHT,30% deposit in advance, balance 70% before shipment.

Q5: How can I place the order?

A5: First sign the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we will ship the Goods.

Q6: When can I get the quotation ?

A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

Best China manufacturer & factory Gearbox in Bogota Colombia For Digger Drive With high quality best price

With EPG brand registered in more than 70 countries like America , Europe , Japan and so on, it has partners among world top enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, etc.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, farms

- Place of Origin:Zhejiang, China

-

The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc.

- Brand Name:

-

OEM

- Output Torque:

-

-

- Input Speed:

-

-

- Output Speed:

-

-

- Product name:

-

Gearbox For Digger Drive

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden case

- Port

- Shanghai/Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 - 1 >1 In our company we are aware of the importance of the users' safety. That's why our PTO's are produced according to legal regulations and European directives and bear the CE sign. A key factor for safety assurance is the accession in the products’ development phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is vital. This means, that every users’ duty is to read and follow the safety instructions. Est. Time(days) 45 To be negotiated

Online Customization

As an employee owned company, we are committed to exceeding our customers’ expectations through every stage of the gear manufacturing process. For custom worms and worm gears made to your exact specifications, you can feel confident turning to Gear Motions.

Product Description

Gearbox For Digger Drive

We manufacture drive system for digger encluded Hydraulic digger for construction and industry, post hole digger, and potato digger etc.... Gearbox for digger drive

|

Product Name |

Gearbox For Digger Drive |

Related Products

|

Gearbox For Rotary Tiller |

Gearbox For Fertiliser Spreaders |

Agricultural Gearbox For HAY TEDDER |

|

Agricultural Gearbox For Rotary Cutter |

Gearbox For Rotary Mowers |

Agricultural Pto Gearboxes For Powered Generator |

|

Post Hole Digger Gearbox |

Gearbox For Self Loading Trailer |

General Gearbox For Agricultural Machinery |

|

Agricultural Gearbox For Manure Spreader |

Gearboxes For Silo Distributors System |

Driveline Motor Of Irrigation System |

|

Agricultural Gearbox For Fertilizer Spreader |

Hay Choppers Gearboxes |

Driveline Gearbox Of Irrigation System |

|

Agricultural Gearbox For Sprayers |

Gearboxes For Balers |

Center-Dive Gear Box Of Irrigation System |

|

Agricultural Gearbox For Flail Mower |

Gearboxes Multiplier For Hydraulic Pump System |

Hydraulic PTO Drive Gearbox Speed Increaser |

|

Agricultural Gearbox For Lawn Mowers |

Planetary Gearbox For Hydraulic Drive Digger In Line |

Side-Delivery Rake Gearbox |

|

Agricultural Gearbox For Generator |

Agricultural Gearbox For Harvest Fruits |

Planetary Gearboxes For Feed Mixer |

|

Agricultural Gearbox For Micro Tiller |

Gearbox For Cattle Cleaning |

PTO speed reducer |

|

Agricultural Gearbox For Concrete Mixer |

Gearbox For Digger Drive |

Slasher gearboxes |

|

Agricultural Gearbox For Feed Mixer |

Gearbox For Dryer Drive System |

Auger Gearboxes |

|

Agitators For Sewage |

Gearbox For Lagoon Pumps |

Grain Harvester Reversing Gearbox |

|

Salt Spreader Gearboxes |

Bevel Gearbox For Biogas Energy Generator Plant |

Oil-Pump-Gearbox |

|

Gearbox reducer for Climate screens drive system |

Gearbox For Circular Saw And Belt Saws |

Potato Harvester Gearbox |

|

Gearbox And Reducer For Crop Storage Drive Systems |

Gearbox For Snow Tillers |

Pesticide Sprayer Gearbox |

|

Gearbox Reducer For Horticulture Drive Systems |

Gearbox For Concrete Mixers |

Chain Sprockets Gearbox |

|

Drive Systems For Ventilation In Livestock Farming |

Worm Gear Slewing Drive For Timber Grab |

Agricultural Gearbox Grain Conveyor Gearbox |

|

Electric Film Reeler Roll Up Units Winch For Poly Film Greenhouse Ventilation |

Agriculture Gearbox For Rotary Harrows |

Harvester Gearbox Reversing Bevel Gearbox |

|

Rotary Harrows Gearbox |

Agricultural Gearbox For Vineyard |

Reversing Gearbox |

|

Rotary Cultivators Gearbox |

Agricultural Gearbox For Weed Mowers |

Rotary Mower Gearboxes Size EP70 |

|

Gearbox For Trenchers |

Agricultural Gearbox For Offset Mowers |

Poultry and Pig Geared Motors For Feeding Systems |

|

Interpump Gearbox For PTO Drive |

Agricultural Gearbox For Flail Mowers |

Salt Spreader Sprocket Chain Gearbox |

|

Gearbox For Dusters |

Our Company

Ever-power is specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto drive shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vaccum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm gearboxes and so on. furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers' drawings.

We provides a reliable gurantee for the product' s quality by advanced inspection and testing equipment. professional technical team, exquisite processing technology and strict control system.

In recent years, the company has been developing rapidly by its rich experience in production, adcanced managemant system , standardized management system, strong technical force. We always adhere the concept of survial by quality, and decelopment by innovation in science and technology.

Ever-power is willing to work with you hand in hand and create brilliance together!

Grinding Workshop

CNC Teeth Machine

CNC Lathe Workshop

Figuring Center

CNC Workshop

Heat Treatment Machine

3D Measurement Machinery

Gear Teeth Profile Test Machines

Heat Treatment Workshop

Tooth Profile Workshop

Material available

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements.

Surface treatment

Blacking, galvanization, chroming, electrophoresis, color painting, ...

Heat treatment

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, ...

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products , the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Packing & Delivery

Services

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china .

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN , KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

......

-Ø Our Company with over twelve year's history and 1000 workers and 20 sales.

-Ø With over 100 Million USD sales in 2017

-Ø With advance machinery equipments

-Ø With large work capacity and high quality control, ISO certified.

.... .

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

Best China manufacturer & factory china manufacturer NRV090 low noise universal forklift excavator swing gearbox With high quality best price

Service & Quality controlWe supply detailed drawings and offer whenever necessary.

Overview

Quick Details

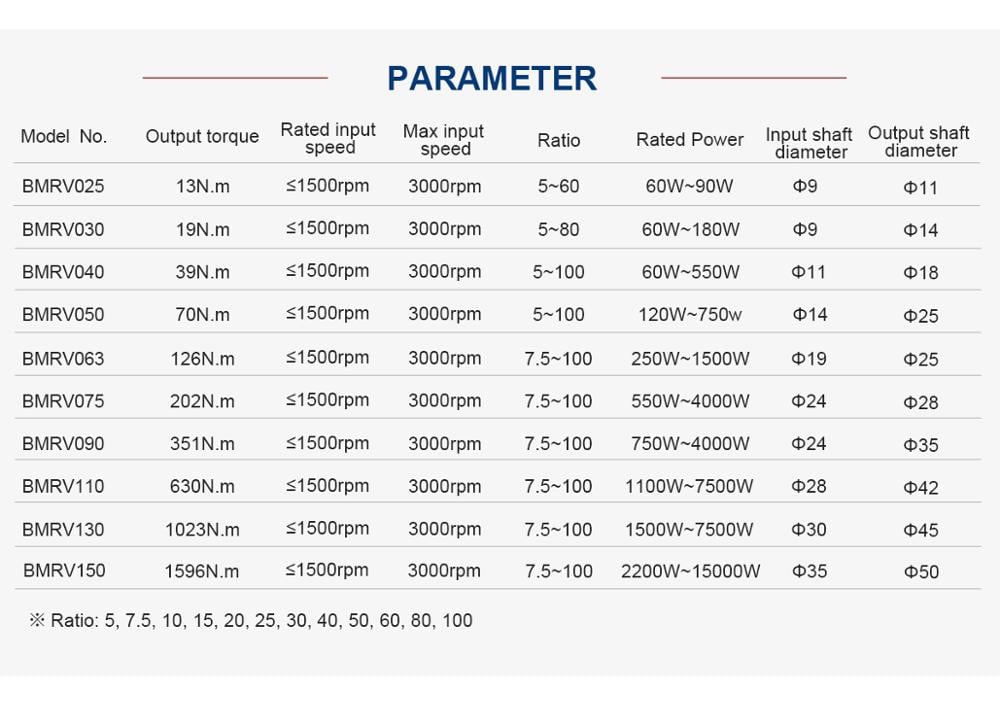

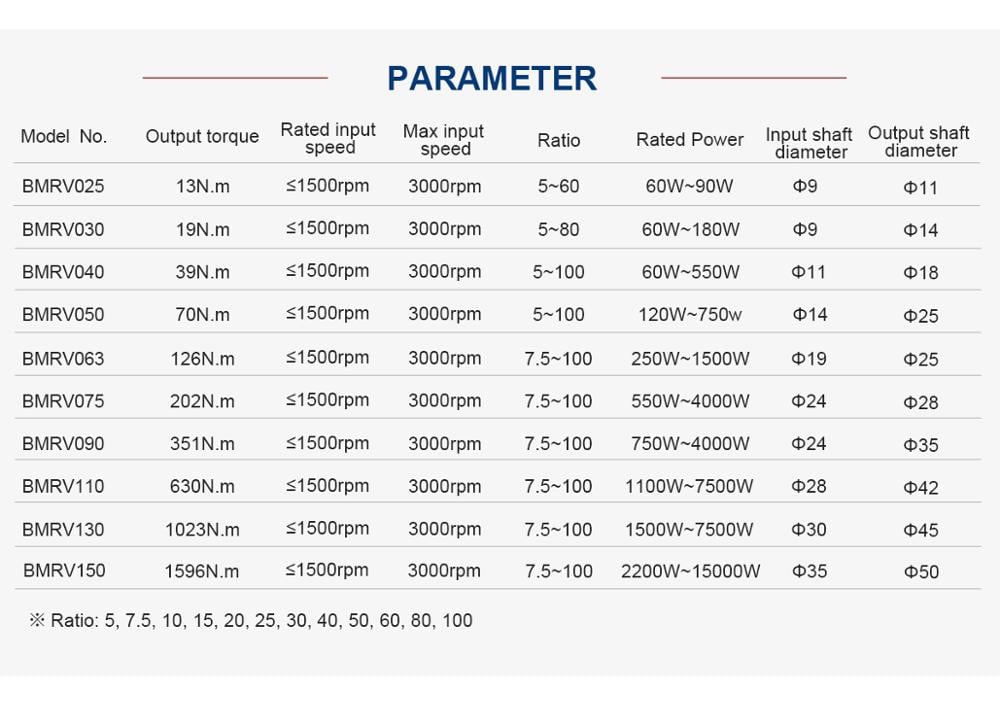

- Applicable Industries:

-

precision machinery

- Gearing Arrangement:

-

worm

- Output Torque:

-

351N.m

It is our aim to supply a vast range of quality products at affordable prices, provide the best service for customers satisfied and contribute to our continued improvement.

- Input Speed:

-

≤1500 rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

excavator swing gearbox

- Ingress Protection:

-

IP65

- Ratio:

-

7.5~100

- Color:

-

gray /blue/black

- Heat treatment:

-

surface hardening

- Housing Material:

-

aluminum alloy

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

-

Lead Time

: -

Quantity(Sets) 1 - 1000 >1000 Est. Time(days) 30 To be negotiated

Online Customization

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced management software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And - 100% inspect finished spare parts before put in storage. - 100% inspect before assembly. - 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxesAs an R&D driven company, we strive to create drive solutions that closely meet are widely used in the areas of textileOur PTO drive shafts enable the user easy maintenance. The greasing nipples on standard crosses are positioned under angle to enable the user better access. Easier access is also possible because of the flexible cone. We listened to the wishes of our customers and placed the greasing nipple at wide-angle PTO’s into the cross bearing. The other novelty, we introduced with wide-angle PTO drive shafts is in line greasing. We wanted to additionally simplify the maintenance and extend the lifespan of joints., food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

Best China manufacturer & factory WPA series single worm gear box 3 8 to 1 4 reducer transmission for gearbox 1:50 ratio speed reducer a234 wpb reducer gear box With high quality best price

With detailed requirments, we can also develop your special designed product. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes....

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

worm

- Output Torque:

-

up to 5000Nm

- Input Speed:

-

750rpm -2000rpm

- Output Speed:

-

10-500rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Customer Request

- Housing Material:

-

Cast Iron

- Shaft:

-

Inline

- Heat treatment:

-

Quenching

- Bearing material:

-

SKF,ZWZ

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Packaging & Delivery

- Packaging Details

- Standard export Packing(Carton Blanket+ wooden box)

- Port

- Ningbo or Shanghai

-

Lead Time

: -

Advantages of Worm Gears

Quantity(Boxes) 1 - 1000 >1000 Est. Time(days) 25 To be negotiated Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers

Online Customization

Specification

gearbox reducer transmission gearbox electric motor reduction gearbox

1.Housing:iron cast

2. low noise(<50DB)

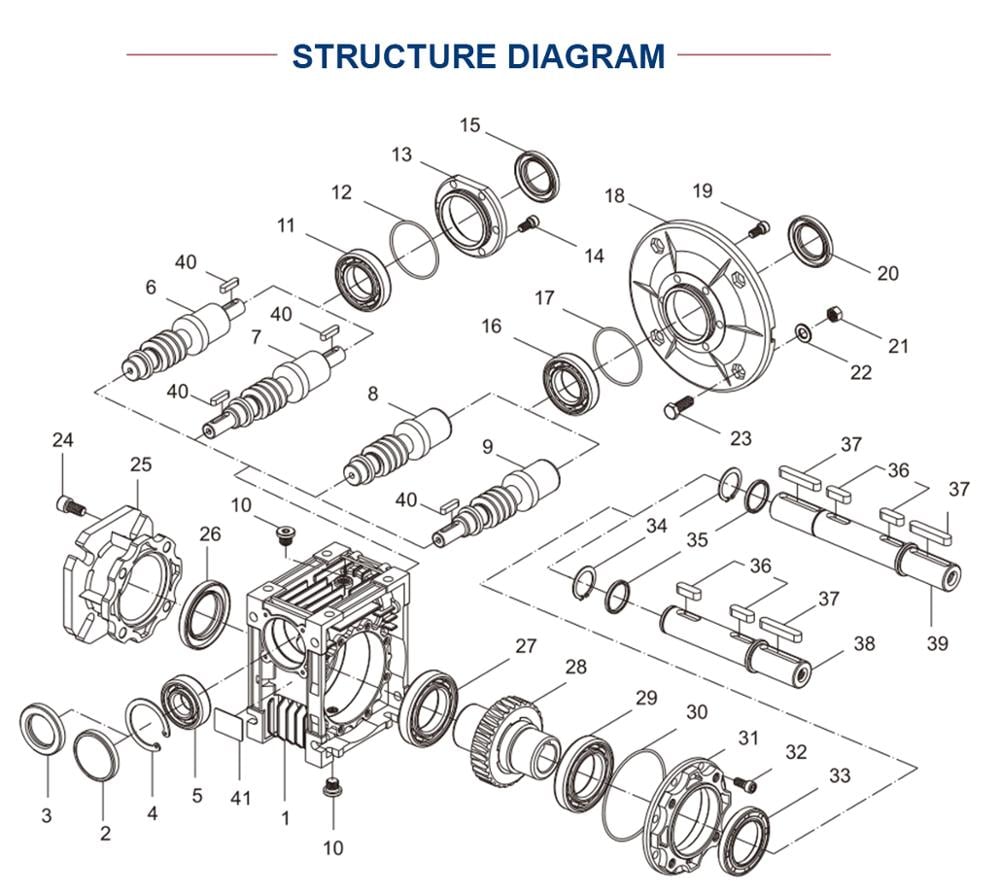

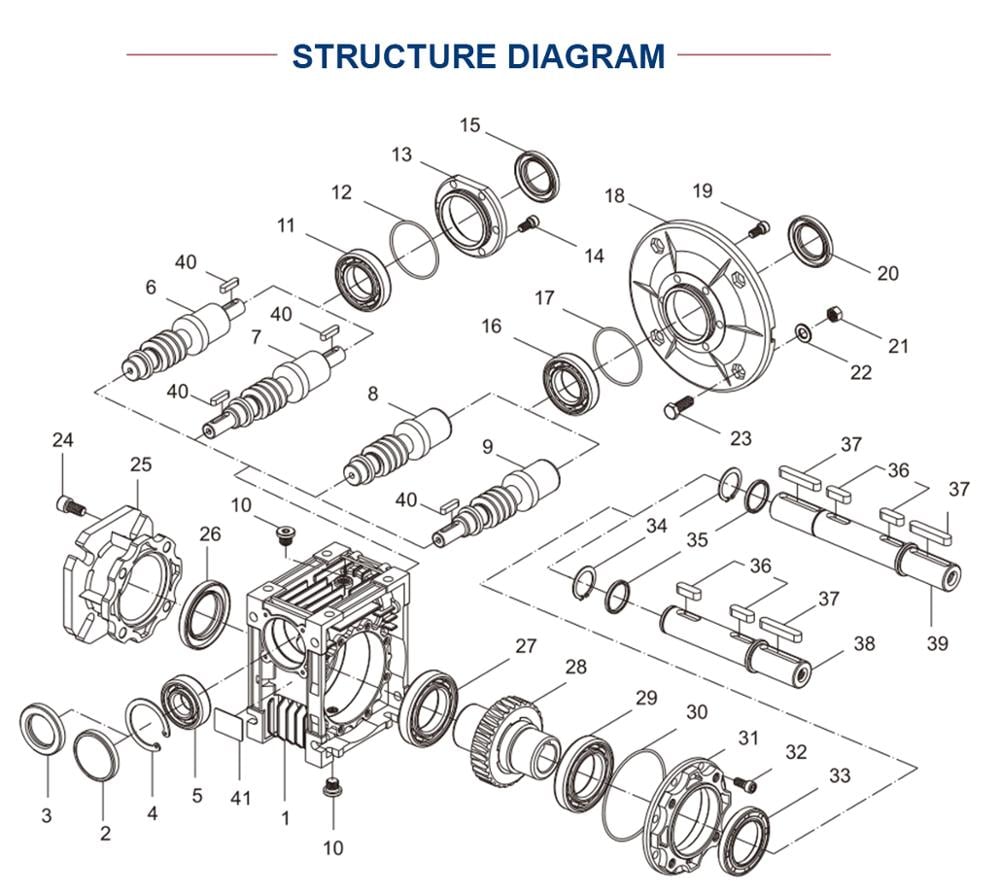

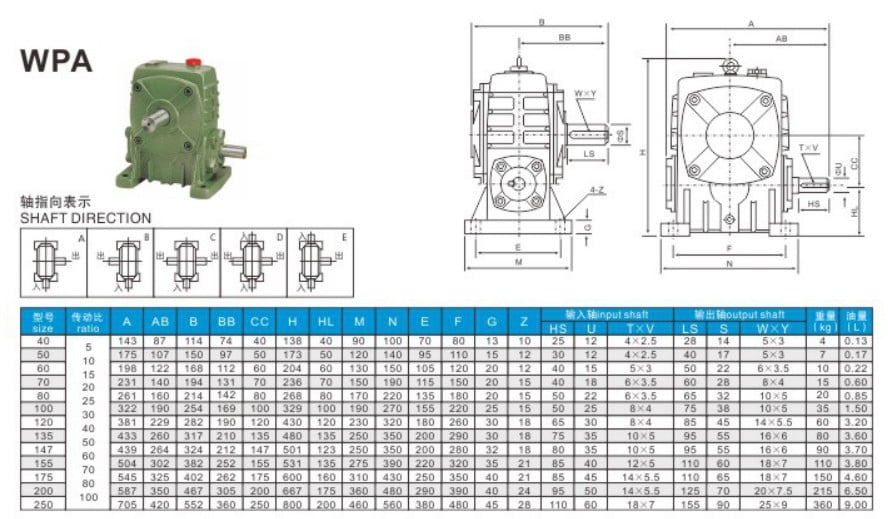

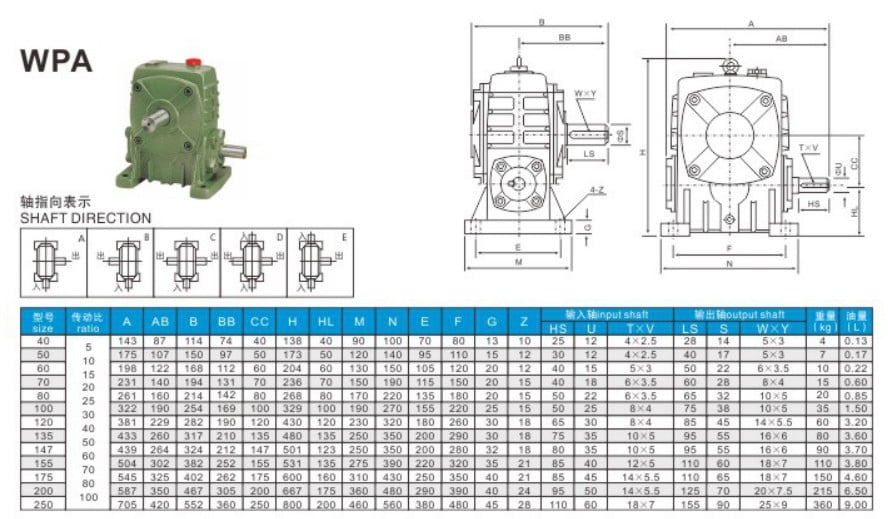

3.Model:WPA 40-250,Ratio:10 to 60

4.Efficient and safe operating

5.ISO9001,Factory price,OEM

6.Technology Data:

| Type: | gearbox WPA |

| Model: | WPA 40-250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Silver Or On Customer Request |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear-Copper-10-3# | |

| Worm-20CrMn Ti with carburizing and quenching, surface harness is 56-62HRC | |

| Shaft-chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U Bearing |

| Seal: | NAK SKF |

| Warranty: | 1 Year |

| Input Power: |

0.06KW,0.09KW |

| Usages: | Industrial Machine: Food Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B14, 63B14, 63B5, 63B5, 71B14,80B14 AND SO ON |

| Lubricant: | Synthetic&Mineral |

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact