Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Products

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Gear

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft's production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CZPT products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

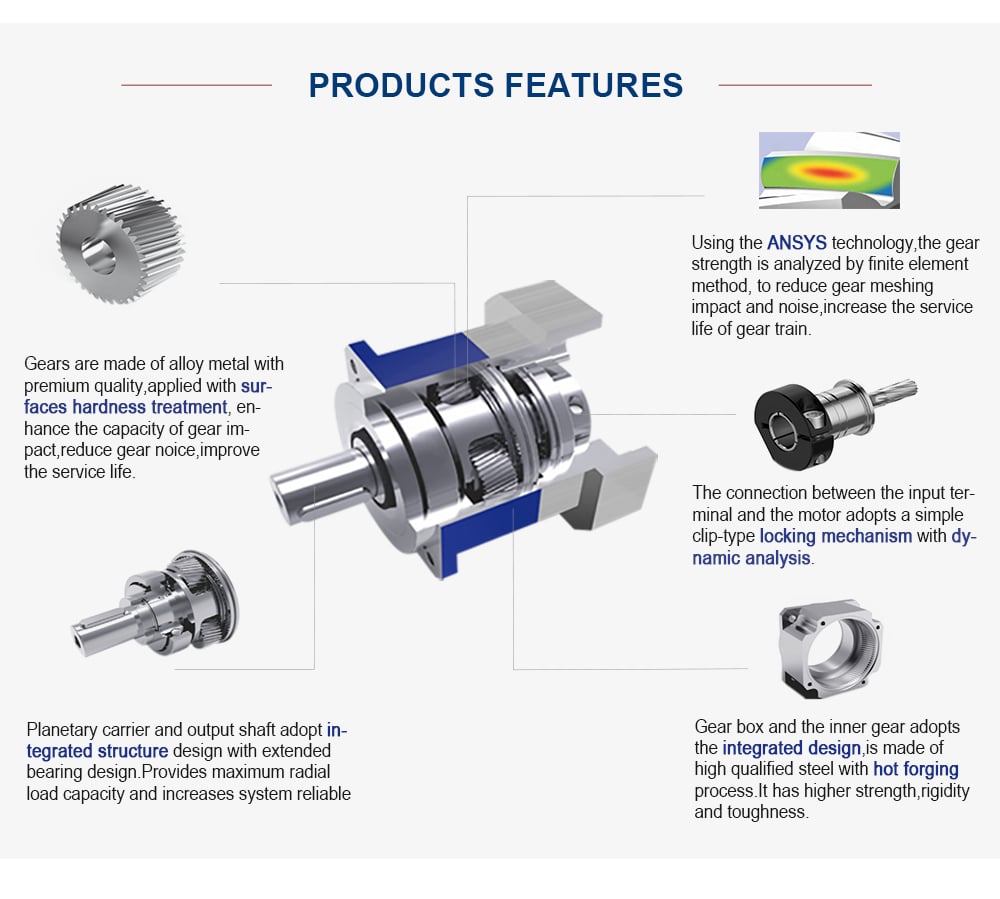

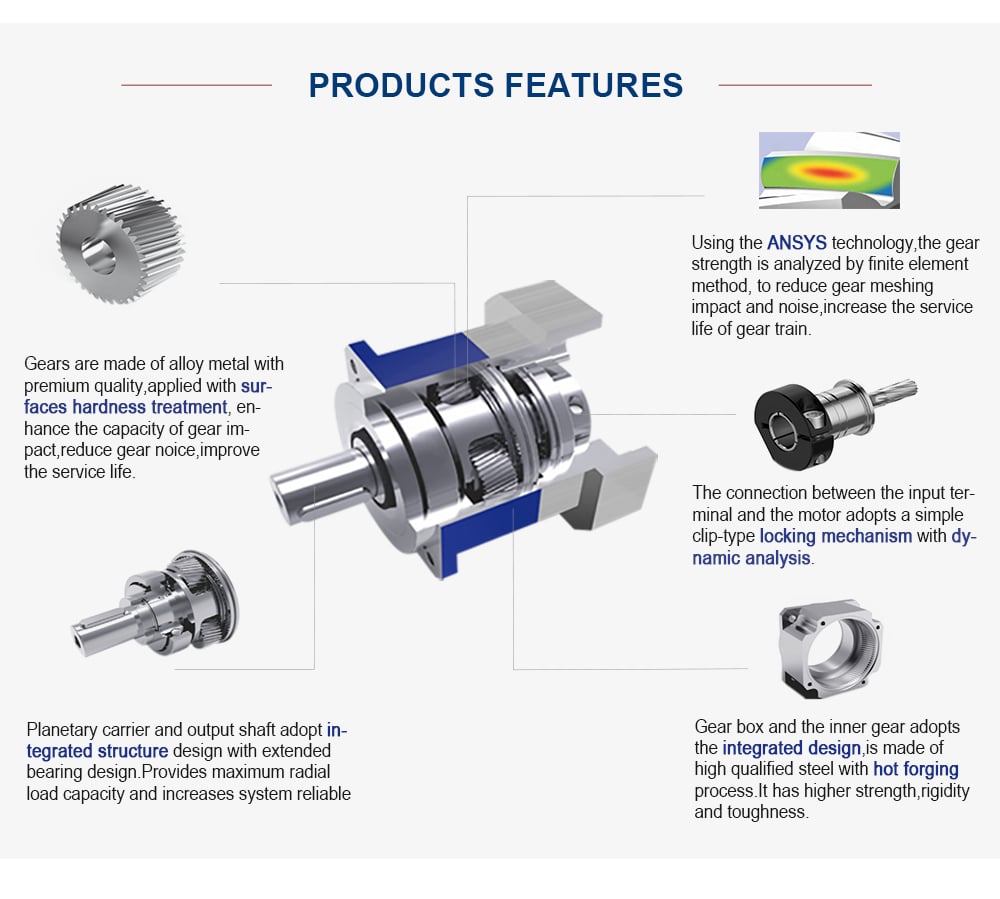

Our Advantages

1) In-house capability: OEM service as per customers' requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer's requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don't have drawing, what can you do for me?

A: If you don't have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there's any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Material: | 17CrNiMo6 |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

hollow drive shaft

Hollow driveshafts have many benefits. They are light and reduce the overall weight of the vehicle. The largest manufacturer of these components in the world is CZPT. They also offer lightweight solutions for various applications, such as high-performance axles. CZPT driveshafts are manufactured using state-of-the-art technology. They offer excellent quality at competitive prices.

The inner diameter of the hollow shaft reduces the magnitude of the internal forces, thereby reducing the amount of torque transmitted. Unlike solid shafts, hollow shafts are getting stronger. The material inside the hollow shaft is slightly lighter, which further reduces its weight and overall torque. However, this also increases its drag at high speeds. This means that in many applications hollow driveshafts are not as efficient as solid driveshafts.

A conventional hollow drive shaft consists of a first rod 14 and a second rod 14 on both sides. The first rod is connected with the second rod, and the second rod extends in the rotation direction. The two rods are then friction welded to the central area of the hollow shaft. The frictional heat generated during the relative rotation helps to connect the two parts. Hollow drive shafts can be used in internal combustion engines and environmentally-friendly vehicles.

The main advantage of a hollow driveshaft is weight reduction. The splines of the hollow drive shaft can be designed to be smaller than the outside diameter of the hollow shaft, which can significantly reduce weight. Hollow shafts are also less likely to jam compared to solid shafts. Hollow driveshafts are expected to eventually occupy the world market for automotive driveshafts. Its advantages include fuel efficiency and greater flexibility compared to solid prop shafts.

Cardan shaft

Cardan shafts are a popular choice in industrial machinery. They are used to transmit power from one machine to another and are available in a variety of sizes and shapes. They are available in a variety of materials, including steel, copper, and aluminum. If you plan to install one of these shafts, it is important to know the different types of Cardan shafts available. To find the best option, browse the catalog.

Telescopic or "Cardan" prop shafts, also known as U-joints, are ideal for efficient torque transfer between the drive and output system. They are efficient, lightweight, and energy-efficient. They employ advanced methods, including finite element modeling (FEM), to ensure maximum performance, weight, and efficiency. Additionally, the Cardan shaft has an adjustable length for easy repositioning.

Another popular choice for driveshafts is the Cardan shaft, also known as a driveshaft. The purpose of the driveshaft is to transfer torque from the engine to the wheels. They are typically used in high-performance car engines. Some types are made of brass, iron, or steel and have unique surface designs. Cardan shafts are available in inclined and parallel configurations.

Single Cardan shafts are a common replacement for standard Cardan shafts, but if you are looking for dual Cardan shafts for your vehicle, you will want to choose the 1310 series. This type is great for lifted jeeps and requires a CV-compatible transfer case. Some even require axle spacers. The dual Cardan shafts are also designed for lifts, which means it's a good choice for raising and lowering jeeps.

universal joint

Cardan joints are a good choice for drive shafts when operating at a constant speed. Their design allows a constant angular velocity ratio between the input and output shafts. Depending on the application, the recommended speed limit may vary depending on the operating angle, transmission power, and application. These recommendations must be based on pressure. The maximum permissible speed of the drive shaft is determined by determining the angular acceleration.

Because gimbal joints don't require grease, they can last a long time but eventually fail. If they are poorly lubricated or dry, they can cause metal-to-metal contact. The same is true for U-joints that do not have oil filling capability. While they have a long lifespan, it can be difficult to spot warning signs that could indicate impending joint failure. To avoid this, check the drive shaft regularly.

U-joints should not exceed seventy percent of their lateral critical velocity. However, if this speed is exceeded, the part will experience unacceptable vibration, reducing its useful life. To determine the best U-joint for your application, please contact your universal joint supplier. Typically, lower speeds do not require balancing. In these cases, you should consider using a larger pitch diameter to reduce axial force.

To minimize the angular velocity and torque of the output shaft, the two joints must be in phase. Therefore, the output shaft angular displacement does not completely follow the input shaft. Instead, it will lead or lag. Figure 3 illustrates the angular velocity variation and peak displacement lead of the gimbal. The ratios are shown below. The correct torque for this application is 1360 in-Ibs.

Refurbished drive shaft

Refurbished driveshafts are a good choice for a number of reasons. They are cheaper than brand new alternatives and generally just as reliable. Driveshafts are essential to the function of any car, truck, or bus. These parts are made of hollow metal tubes. While this helps reduce weight and expense, it is vulnerable to external influences. If this happens, it may crack or bend. If the shaft suffers this type of damage, it can cause serious damage to the transmission.

A car's driveshaft is a critical component that transmits torque from the engine to the wheels. A1 Drive Shaft is a global supplier of automotive driveshafts and related components. Their factory has the capability to refurbish and repair almost any make or model of driveshafts. Refurbished driveshafts are available for every make and model of vehicle. They can be found on the market for a variety of vehicles, including passenger cars, trucks, vans, and SUVs.

Unusual noises indicate that your driveshaft needs to be replaced. Worn U-joints and bushings can cause excessive vibration. These components cause wear on other parts of the drivetrain. If you notice any of these symptoms, please take your vehicle to the AAMCO Bay Area Center for a thorough inspection. If you suspect damage to the driveshaft, don't wait another minute - it can be very dangerous.

The cost of replacing the drive shaft

The cost of replacing a driveshaft varies, but on average, this repair costs between $200 and $1,500. While this price may vary by vehicle, the cost of parts and labor is generally equal. If you do the repair yourself, you should know how much the parts and labor will cost before you start work. Some parts can be more expensive than others, so it's a good idea to compare the cost of several locations before deciding where to go.

If you notice any of these symptoms, you should seek a repair shop immediately. If you are still not sure if the driveshaft is damaged, do not drive the car any distance until it is repaired. Symptoms to look for include lack of power, difficulty moving the car, squeaking, clanking, or vibrating when the vehicle is moving.

Parts used in drive shafts include center support bearings, slip joints, and U-joints. The price of the driveshaft varies by vehicle and may vary by model of the same year. Also, different types of driveshafts require different repair methods and are much more expensive. Overall, though, a driveshaft replacement costs between $300 and $1,300. The process may take about an hour, depending on the vehicle model.

Several factors can lead to the need to replace the drive shaft, including bearing corrosion, damaged seals, or other components. In some cases, the U-joint indicates that the drive shaft needs to be replaced. Even if the bearings and u-joints are in good condition, they will eventually break and require the replacement of the drive shaft. However, these parts are not cheap, and if a damaged driveshaft is a symptom of a bigger problem, you should take the time to replace the shaft.

editor by CX 2023-05-18

China Worm Gear Drive Wheel Good Price Ground Shaft Helical Micro for Gearbox Speed Reducer Outdoor Ride Car Spare Part Worm Gear drive shaft shop

Merchandise Description

Our Rewards

Our advantange, Reduced MOQ as significantly less as 1 piece, one hundred% inspection, Quick Direct time.

Our support

We manufacture a variety of shafts made according to drawing, like roud shaft, sq. shaft, hollow shaft, screw shaft, spline shaft, gear shaft, etc.

| Materials | Alloy, stainless steel, Carbon steel, etc. |

| Mahines | NC lathe, Milling macine, Ginder, CNC, Equipment milling device. |

| Third get together inspection | Available, SGS, CNAS, BV, and so forth. |

| UT common | ASTM A388, AS1065, GB/T6402, and many others. |

| Packaging | Seaworthy packing |

| Drawing format | PDF, DWG, DXF, STP, IGS, and so forth. |

| Application | Industry usage, Equipment utilization. |

| MOQ | 1 piece |

| Drawing format | PDF, DWG, DXF, STP, IGS, and so on. |

| Quotation time | 1 times. |

| Lead time | Generaly 30-forty days for mass manufacturing. |

Our Merchandise

Throughout the go ten years, we have supplied hundreds of buyers with excellent precision machining jobs:

Workshop & machining approach

We manufacture various shafts produced in accordance to drawing, such as roud shaft, square shaft, hollow shaft, screw shaft, spline shaft, equipment shaft, etc.

FAQ

Q: Are you treading organization or manufacturer?

A: We are manufacturer.

Q: How about your MOQ?

A: We give both prototype and mass production, Our MOQ is 1 piece.

Q:How lengthy can I get a quote following RFQ?

A:we normally estimate you inside 24 hrs. A lot more element information provided will be valuable to help save your time.

one) in depth engineering drawing with tolerance and other necessity.

2) the amount you desire.

Q:How is your top quality guarantee?

A:we do one hundred% inspection before shipping, we are hunting for prolonged term company relationship.

Q:Can I sign NDA with you?

A:Certain, we will keep your drawing and information confidential.

|

US $5-40 / Piece | |

1 Piece (Min. Order) |

###

| Casting Method: | Thermal Gravity Casting |

|---|---|

| Process: | CNC |

| Molding Technics: | Gravity Casting |

| Application: | Machinery Parts |

| Material: | Carbon Steel |

| Surface Preparation: | Polishing |

###

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Material | Alloy, stainless steel, Carbon steel, etc. |

| Mahines | NC lathe, Milling macine, Ginder, CNC, Gear milling machine. |

| Third party inspection | Available, SGS, CNAS, BV, etc. |

| UT standard | ASTM A388, AS1065, GB/T6402, etc. |

| Packaging | Seaworthy packing |

| Drawing format | PDF, DWG, DXF, STP, IGS, etc. |

| Application | Industry usage, Machine usage. |

| MOQ | 1 piece |

| Drawing format | PDF, DWG, DXF, STP, IGS, etc. |

| Quotation time | 1 days. |

| Lead time | Generaly 30-40 days for mass production. |

|

US $5-40 / Piece | |

1 Piece (Min. Order) |

###

| Casting Method: | Thermal Gravity Casting |

|---|---|

| Process: | CNC |

| Molding Technics: | Gravity Casting |

| Application: | Machinery Parts |

| Material: | Carbon Steel |

| Surface Preparation: | Polishing |

###

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Material | Alloy, stainless steel, Carbon steel, etc. |

| Mahines | NC lathe, Milling macine, Ginder, CNC, Gear milling machine. |

| Third party inspection | Available, SGS, CNAS, BV, etc. |

| UT standard | ASTM A388, AS1065, GB/T6402, etc. |

| Packaging | Seaworthy packing |

| Drawing format | PDF, DWG, DXF, STP, IGS, etc. |

| Application | Industry usage, Machine usage. |

| MOQ | 1 piece |

| Drawing format | PDF, DWG, DXF, STP, IGS, etc. |

| Quotation time | 1 days. |

| Lead time | Generaly 30-40 days for mass production. |

Driveshaft structure and vibrations associated with it

The structure of the drive shaft is critical to its efficiency and reliability. Drive shafts typically contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Learn about the different types of drive shafts and how they work. If you want to know the vibrations associated with them, read on. But first, let's define what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the demand on our drive systems. Higher CO2 emission standards and stricter emission standards increase the stress on the drive system while improving comfort and shortening the turning radius. These and other negative effects can place significant stress and wear on components, which can lead to driveshaft failure and increase vehicle safety risks. Therefore, the drive shaft must be inspected and replaced regularly.

Depending on your model, you may only need to replace one driveshaft. However, the cost to replace both driveshafts ranges from $650 to $1850. Additionally, you may incur labor costs ranging from $140 to $250. The labor price will depend on your car model and its drivetrain type. In general, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into four major markets: North America, Europe, Asia Pacific, and Rest of the World. North America is expected to dominate the market, while Europe and Asia Pacific are expected to grow the fastest. Furthermore, the market is expected to grow at the highest rate in the future, driven by economic growth in the Asia Pacific region. Furthermore, most of the vehicles sold globally are produced in these regions.

The most important feature of the driveshaft is to transfer the power of the engine to useful work. Drive shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or both. Due to the complexity of driveshaft assemblies, they are critical to vehicle safety. In addition to transmitting torque from the engine, they must also compensate for deflection, angular changes and length changes.

type

Different types of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head provide a rotationally secure connection. At least one bearing has a groove extending along its circumferential length that allows the pin to pass through the bearing. There can also be two flanges on each end of the shaft. Depending on the application, the shaft can be installed in the most convenient location to function.

Propeller shafts are usually made of high-quality steel with high specific strength and modulus. However, they can also be made from advanced composite materials such as carbon fiber, Kevlar and fiberglass. Another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a high strength-to-weight ratio. Both drive shafts and screw shafts are used to drive cars, ships and motorcycles.

Sliding and tubular yokes are common components of drive shafts. By design, their angles must be equal or intersect to provide the correct angle of operation. Unless the working angles are equal, the shaft vibrates twice per revolution, causing torsional vibrations. The best way to avoid this is to make sure the two yokes are properly aligned. Crucially, these components have the same working angle to ensure smooth power flow.

The type of drive shaft varies according to the type of motor. Some are geared, while others are non-geared. In some cases, the drive shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to control the speed and direction of the drive. In some applications where linear power transmission is not possible, flexible shafts are a useful option. For example, flexible shafts can be used in portable devices.

put up

The construction of the drive shaft has many advantages over bare metal. A shaft that is flexible in multiple directions is easier to maintain than a shaft that is rigid in other directions. The shaft body and coupling flange can be made of different materials, and the flange can be made of a different material than the main shaft body. For example, the coupling flange can be made of steel. The main shaft body is preferably flared on at least one end, and the at least one coupling flange includes a first generally frustoconical projection extending into the flared end of the main shaft body.

The normal stiffness of fiber-based shafts is achieved by the orientation of parallel fibers along the length of the shaft. However, the bending stiffness of this shaft is reduced due to the change in fiber orientation. Since the fibers continue to travel in the same direction from the first end to the second end, the reinforcement that increases the torsional stiffness of the shaft is not affected. In contrast, a fiber-based shaft is also flexible because it uses ribs that are approximately 90 degrees from the centerline of the shaft.

In addition to the helical ribs, the drive shaft 100 may also contain reinforcing elements. These reinforcing elements maintain the structural integrity of the shaft. These reinforcing elements are called helical ribs. They have ribs on both the outer and inner surfaces. This is to prevent shaft breakage. These elements can also be shaped to be flexible enough to accommodate some of the forces generated by the drive. Shafts can be designed using these methods and made into worm-like drive shafts.

vibration

The most common cause of drive shaft vibration is improper installation. There are five common types of driveshaft vibration, each related to installation parameters. To prevent this from happening, you should understand what causes these vibrations and how to fix them. The most common types of vibration are listed below. This article describes some common drive shaft vibration solutions. It may also be beneficial to consider the advice of a professional vibration technician for drive shaft vibration control.

If you're not sure if the problem is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should contact an expert as soon as possible. If vibration persists after vibration-related repairs, the driveshaft needs to be replaced. If the driveshaft is still under warranty, you can repair it yourself.

CV joints are the most common cause of third-order driveshaft vibration. If they are binding or fail, they need to be replaced. Alternatively, your CV joints may just be misaligned. If it is loose, you can check the CV connector. Another common cause of drive shaft vibration is improper assembly. Improper alignment of the yokes on both ends of the shaft can cause them to vibrate.

Incorrect trim height can also cause driveshaft vibration. Correct trim height is necessary to prevent drive shaft wobble. Whether your vehicle is new or old, you can perform some basic fixes to minimize problems. One of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Next, attach an ounce of weight to it and spin it. By doing this, you minimize the frequency of vibration.

cost

The global driveshaft market is expected to exceed (xxx) million USD by 2028, growing at a compound annual growth rate (CAGR) of XX%. Its soaring growth can be attributed to several factors, including increasing urbanization and R&D investments by leading market players. The report also includes an in-depth analysis of key market trends and their impact on the industry. Additionally, the report provides a comprehensive regional analysis of the Driveshaft Market.

The cost of replacing the drive shaft depends on the type of repair required and the cause of the failure. Typical repair costs range from $300 to $750. Rear-wheel drive cars usually cost more. But front-wheel drive vehicles cost less than four-wheel drive vehicles. You may also choose to try repairing the driveshaft yourself. However, it is important to do your research and make sure you have the necessary tools and equipment to perform the job properly.

The report also covers the competitive landscape of the Drive Shafts market. It includes graphical representations, detailed statistics, management policies, and governance components. Additionally, it includes a detailed cost analysis. Additionally, the report presents views on the COVID-19 market and future trends. The report also provides valuable information to help you decide how to compete in your industry. When you buy a report like this, you are adding credibility to your work.

A quality driveshaft can improve your game by ensuring distance from the tee and improving responsiveness. The new material in the shaft construction is lighter, stronger and more responsive than ever before, so it is becoming a key part of the driver. And there are a variety of options to suit any budget. The main factor to consider when buying a shaft is its quality. However, it's important to note that quality doesn't come cheap and you should always choose an axle based on what your budget can handle.

editor by czh 2023-01-28

in Changwon Republic of Korea sales price shop near me near me shop factory supplier Hot Sale R Series Engine Gearbox Speed Reducer manufacturer best Cost Custom Cheap wholesaler

With EPG brand registered in more than 70 international locations like America , Europe , Japan and so on, it has associates among globe best enterprises, this sort of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and many others. In this way, our merchandise have ongoing to obtain industry acceptance and consumers satisfaction more than the past handful of a long time. EPG is a skilled manufacturer and exporter that is anxious with the layout, growth and creation. Merchandise Description:

EPTT Collection EPT motor is the EPT products with global EPTd amount.incXiHu (West EPT) Dis.Hu (West EPT) Dis. R sequence EPTcal EPTed motor, F collection PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel shaft-EPTcal EPTed motor, K series EPTcal-Beval EPTed motor,S sequence EPTcal-Worm.

EPTT series merchandise adhere to EPT the philosophy of modularization and optimization, undertake finite element evaluation technique and EPT

lower noise EPT in developing EPT ,to insure EPTd design and style.The classi fication of ratio is so acurate that.

Our corpotation also offers other item alternatives this sort of as combined EPTed motor,shrink disk,spline hollow shaft, B14 flange,you should consult our organization for additional data.

| EPT content | Forged iron/Ductile iron |

| EPT hardness | HBS190-240 |

| EPT materials | 20CrMnTi alloy metal |

| Surface hardness of EPTs | EPTC58 deg~sixty two deg |

| EPT core hardness | EPTC33~40 |

| Input / Output shaft materials | 42CrMo alloy steel |

| Enter / Output shaft hardness | EPTC25~30 |

| Machining precision of EPTs | exact grinding, six~five Quality |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Warmth treatment | tempering, cementiting, quenching, and so forth. |

| Efficiency | ninety four%~ninety six% (is dependent on the EPTT phase) |

| Noise (MAX) | sixty~68dB |

| Temp. rise (MAX) | 40 degC |

| Temp. rise (Oil)(MAX) | fifty degC |

| Vibration | le20 microm |

| Backlash | le20Arcmin |

| Manufacturer of bearings | EPTT prime brand name bearing, EPTB/LYC/ZWZ/C ampU. Or other brands asked for, SKF, NSK. |

| Brand of oil seal | NAK --- EPTTiwan or other brands asked for |

EPTcal velocity EPTT much more details:

Our factory and in stock :

Application region:

Plywood EPTT and Global delivery :

FAQ

Q1: Are you investing firm or company ?

A: We are a company in EPTTngsu EPTT.welcome to our manufacturing facility to have a visit.

Q2: How we pick models and specs?

A:You can e-mail us the sequence title amp code (for example: WJ series worm EPTT) as well as necessity specifics, such as motor EPTT, output velocity or ratio, provider element or your application...as significantly data as attainable. If you can supply some pictures or drawings, it is EPT.

Q3: How is your value? Can you offer you any discount?

A: Within twelve several hours.

This autumn: How EPTT should I hold out for the suggestions soon after I send out the enquiry?

Semi-EPTT PET Bottle Blowing EPTT Bottle Producing EPTT Bottle EPTing EPTT

PET Bottle Producing EPTT is appropriate for producing PET plastic containers and bottles in all designs.

It is widely employed to create the carbonated bottle, EPTral h2o, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle and many others.

EPTTrage bottle, beauty bottle, drugs bottle, jar and so on.

Lorem Ipsum is basically dummy textual content of the printing and typesetting business. Lorem Ipsum has been the industry's stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd dummy textual content ever considering that the 1500s, when an unfamiliar printer took a galley of variety and scrambled it to make a sort specimen book.

Q5: What is your product warranty time period?

A:We offer 1 yr guarantee given that the vessel departure day left EPTT.

Q6: What EPTT are your EPTTes being used?

A:Our EPTTes are widely used to metallurgical products, mining tools, EPTT equipment, foodstuff EPTTry, EPTT products, tobacco equipment and so on.

If you are interested, could you you should inform me your contact information? I can send out you the parameters and details of this EPT box for your reference.

Best China manufacturer & factory china in Al-Mansurah Egypt manufacturer BADR255 high toique compact precise right angle planetary speed gearbox With high quality best price

We will provide best services and high quality products with all sincerity. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes....

Overview

Quick Details

- Applicable Industries:

-

CNC

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

The PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor.

1500~2000 N.m

- Input Speed:

-

2000rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

planetary 90 degree gearbox

- Material:

-

20CrMnTi, 40Cr

- Ratio:

-

4~200

- Backlash:

-

P1/P2

- Ingress protection:

-

IP65

- Color:

-

champagne gold+black/ silver+blue/ OEM color

- Heat treatment:

-

hot forged/hardening

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

TECHNOLOGY LEADER IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for over 30 years now. This great determination has helped us become an undisputed global technology and quality leader.

-

Lead Time

: -

Quantity(Pieces) 1 - 1000 >1000 Est. Time(days) 30 To be negotiated

Online Customization

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAUMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.LIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced management software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And - 100% inspect finished spare parts before put in storage. - 100% inspect before assembly. - 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

Best China manufacturer & factory WPA series single worm gear box 3 8 to 1 4 reducer transmission for gearbox 1:50 ratio speed reducer a234 wpb reducer gear box With high quality best price

With detailed requirments, we can also develop your special designed product. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes....

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

worm

- Output Torque:

-

up to 5000Nm

- Input Speed:

-

750rpm -2000rpm

- Output Speed:

-

10-500rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Customer Request

- Housing Material:

-

Cast Iron

- Shaft:

-

Inline

- Heat treatment:

-

Quenching

- Bearing material:

-

SKF,ZWZ

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Packaging & Delivery

- Packaging Details

- Standard export Packing(Carton Blanket+ wooden box)

- Port

- Ningbo or Shanghai

-

Lead Time

: -

Advantages of Worm Gears

Quantity(Boxes) 1 - 1000 >1000 Est. Time(days) 25 To be negotiated Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers

Online Customization

Specification

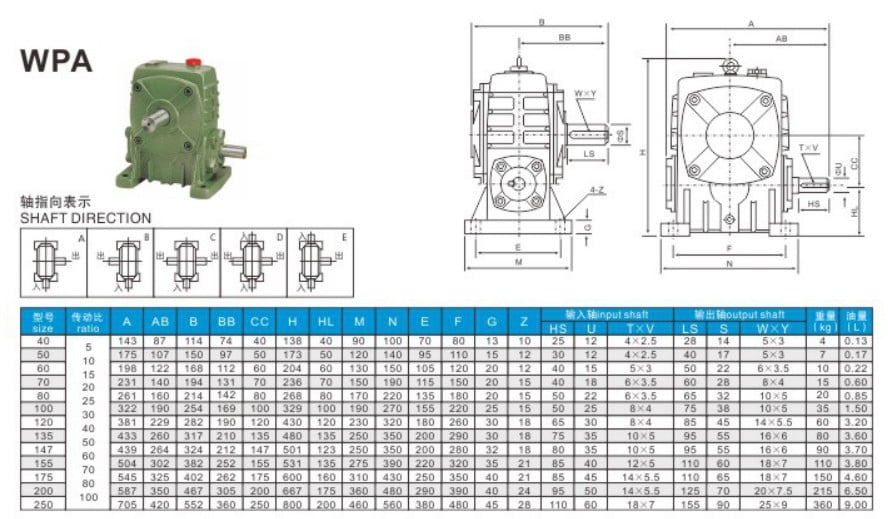

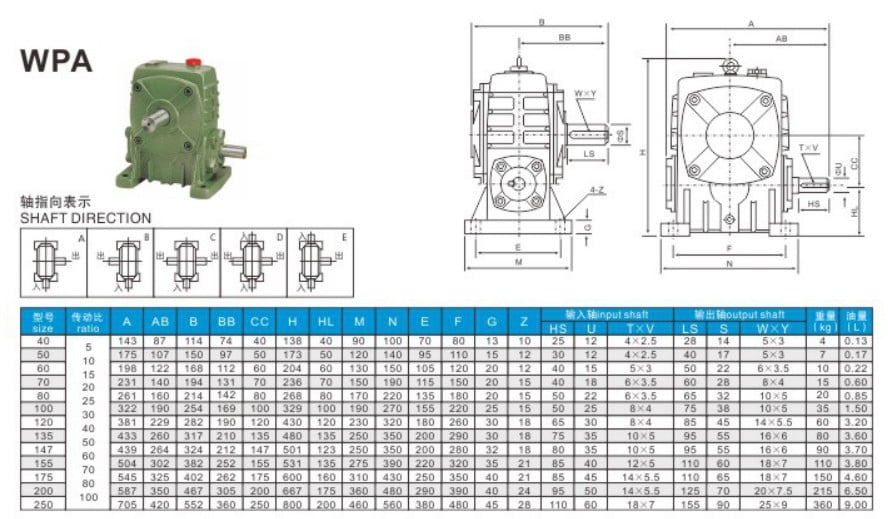

gearbox reducer transmission gearbox electric motor reduction gearbox

1.Housing:iron cast

2. low noise(<50DB)

3.Model:WPA 40-250,Ratio:10 to 60

4.Efficient and safe operating

5.ISO9001,Factory price,OEM

6.Technology Data:

| Type: | gearbox WPA |

| Model: | WPA 40-250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Silver Or On Customer Request |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear-Copper-10-3# | |

| Worm-20CrMn Ti with carburizing and quenching, surface harness is 56-62HRC | |

| Shaft-chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U Bearing |

| Seal: | NAK SKF |

| Warranty: | 1 Year |

| Input Power: |

0.06KW,0.09KW |

| Usages: | Industrial Machine: Food Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B14, 63B14, 63B5, 63B5, 71B14,80B14 AND SO ON |

| Lubricant: | Synthetic&Mineral |

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

Best China manufacturer & factory 2020 china supplier NMRV Type Right Angle Speed Lawn Mower Gearbox worm gear dc motor With high quality best price

EPG is one of the biggest manufacturers in China. We have advanced machines for production and new technology testing ability . Through adopting new technology from British, German, U.S.A, our products are best sellers all over European, America, and Southeast Asia.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Pole:

-

one two three four six Stage

- Ratio:

-

11-87

- Housing Material:

-

Cast Iron

- Working temperature:

-

-40~45℃

--Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.

- Application:

-

production equipment soap

- Process:

-

Carburizing, Nitriding , Grinding

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 - 1 >1 Est. Time(days) 5 To be negotiated

Online Customization

Product Description

YOUR PROFESSIONAL MANUFACTURE

—— SINCE 1995

NMRV Worm Gear Reducer Gearbox

TianQi——industrial manufacturers

Worm Gear Box Reducer Gearbox price with motor for robot arm

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Cycloidal Pinwheel Reducer is a speed reducing construction with advance design,novel structure adopting the principle of planet driving and the falling-in of cycloidal pin gear. It is widely applied to the speed reducing structure of various driving machineries ,such as lift ,transportation,mine,metallurgy,petrolchemical,texitile,prention,lightindustry,pharmacy,food,forage,food machinery,ect.

Specification

NMRV Worm Gear Box Reducer worm gear dc motor:

(please contact us for more types & model)

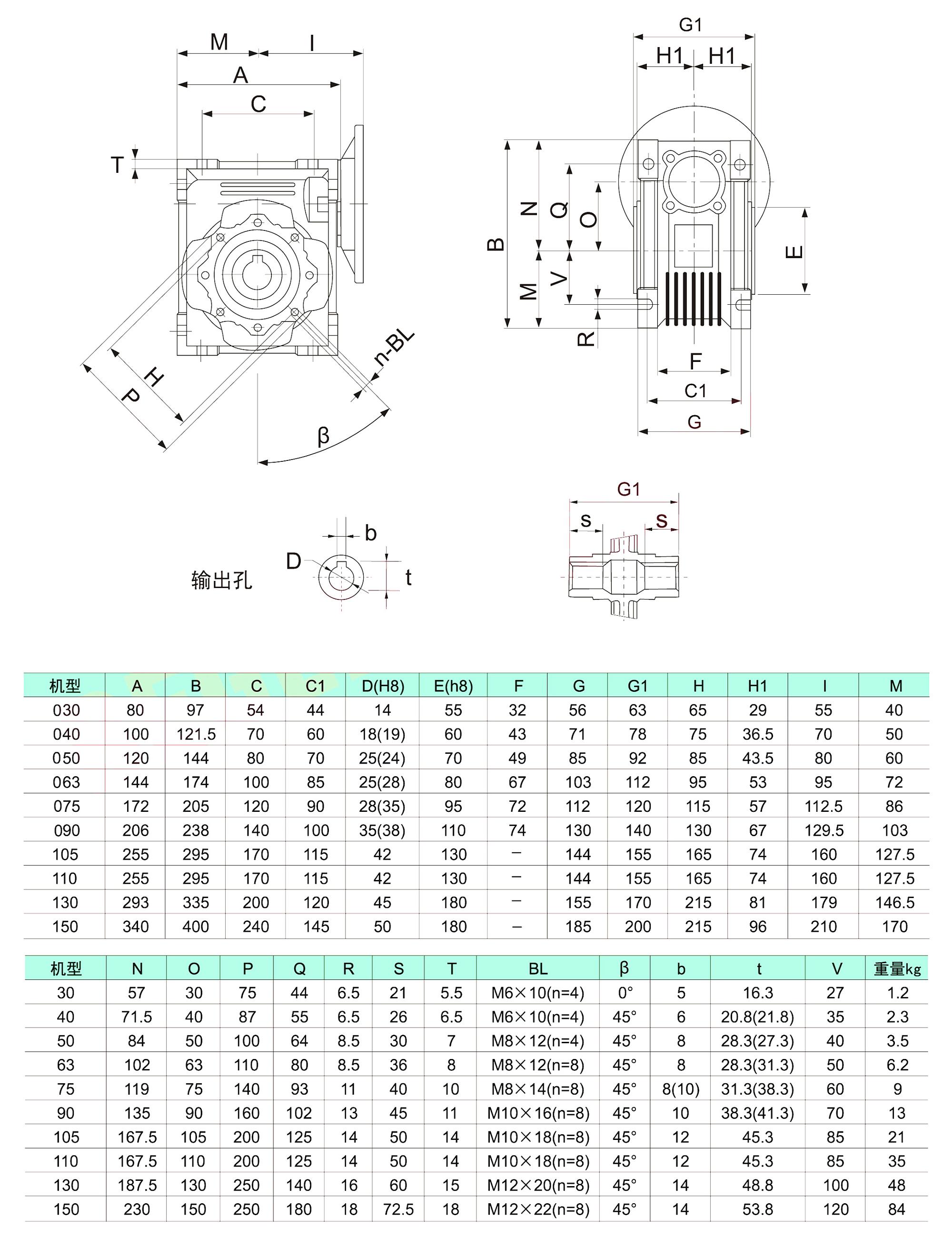

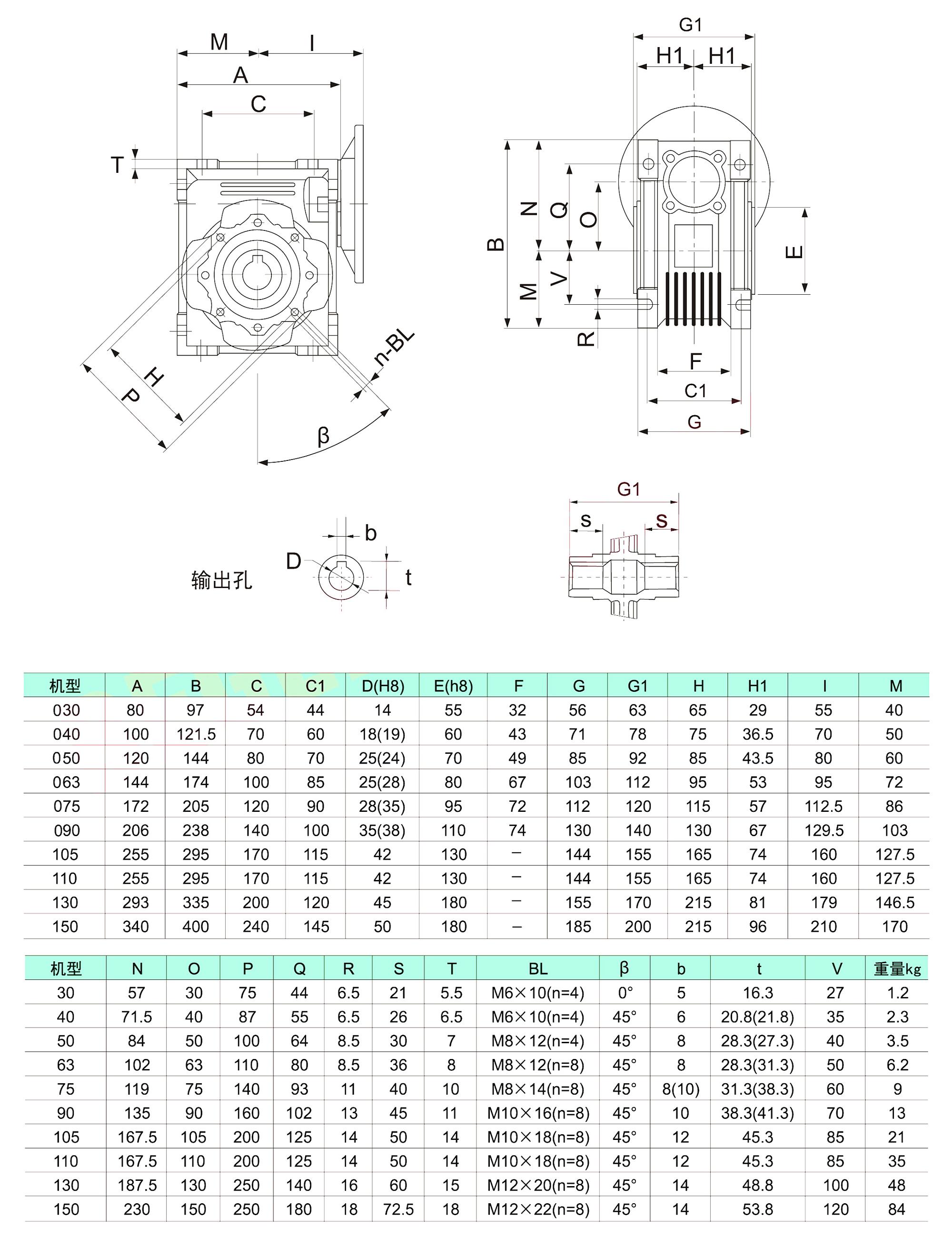

Mounting Diamensions

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.H B series standard industrial gear box reducer.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price. NMRV 063 050 type Worm Gear Box Reducer Gearbox price for robot arm.

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Technology

Feature:

- 1. Big Volecity- Reducing Ratio:Ratio of single-stage speed-reducing is 1/11-1/87; Ratio of double stage speed-reducing is 1/112-1/5133;Ratio of three-stage speed-reducing is 1/2057-1/446571;more-stages can be combined according to the requirement.

-

2. High driving efficiency:Due to adopting rolling engagement in falling-in part, the driving efficiency can reach above 90%.

-

3. Small in size, light weight: with compacted structure,small size and light weight. Due to adopting the principle of planet driving so that the input and output shaft in the same axis which will integrated with the motor.

-

4. Long service life: Has good resistance to abrasion because the main driving engaging parts are made of bearing steel and applying rolling friction.

-

5. Stable running: for most driving procedure, we adopt multi-teeth falling-in. Then the running will be stable with low noise.

-

6. Convenient dismounting:reasonable structure and design.

-

7. Strong overloading ability,anti-compact,suitable for frequently start and double-side rotation.

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machineryThe company was certified by ISO9001:2008 Quality Management System. and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price.Chinese Manufacture cycloid gearbox for iron and steel industry. NMRV 063 050 type Worm Gear Box Reducer Gearbox price for robot arm.

Our Services

Packaging & Shipping

Company Information

EPG is a professiWorm gears are typically manufactured by hobbing with a hob or cutting tool very similar to the worm that the gear mates with. The worm may be turned, hobbed, milled, or ground.onal manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look forward to speaking with you to future discuss how we can be of service to you.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer's drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in Zibo of Shandong Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory NMRV63 worm transmission gearbox with speed reducer motor With high quality best price

Full use has been made of all kinds of advanced techniques and technology to reach excelsior manufacturing.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- ITEM NO:

-

SYF

- Color:

-

Blue

- Product name:

-

Worm Gear Screw Jack

- Application:

-

Machine Tool

- Material:

-

Aluminium Alloy

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

5-100

- Mounting Position:

-

Flange Mounted

- Input Form:

-

IEC Flange

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 - 10 11 - 20 >20 Est. Time(days) 8 15 To be negotiated

Online Customization

Mounting Dimension

The products are widely applied in the producing equipments of all kinds of industries inside and outside China. They are the best choices for nowadays modern facilities of mechanical reducing drive control to realize large twisting distance, large gear ratio, little noise, high efficiency and stability.

|

Model: |

NMRV025, 030, 040, 050, 063, 075, 090, 110, 130, 150 |

|

Ratio: |

1:5,7.5,10,15,20,25,30,40,50,60,80,100 |

|

Color: |

Blue, Silver Or On Customer Request |

|

Noise: |

low noise (<50DB) |

|

Advantage: |

Efficient and safe operating |

|

Material: |

Housing: Die-Cast Aluminum Alloy |

|

Worm Gear-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, surface harness is 56-62HRC |

|

|

Shaft-chromium steel-45# |

|

|

Packing: |

Carton and Wooden Case |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certificate: |

ISO9001,CE,3C,OEM |

|

Warranty: |

12 months |

|

Input Power: |

0.06kw, 0.09kw, 0.12kw, 0.18kw, 0.25kw, 0.37kw, 0.55kw, 0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Machine: Food Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Synthetic & Mineral |

Product Deseription

Single Step Worm Gear Reducer.

The reducer which model is 25~90 made of Aluminum alloy die-casting box,good looking in appearance,compact in structure,rust proofing on surface and small volume to save mounting space.

The reducer model of 110~150 is made of cast iron which casted with Aluminum mould.It`s good looking and solid, and can be used through the setting of multi-azimuth.

Good radiating characterstic leads safe and reliability,and high efficiency for using.

The strong capacity of loading ensure stable transmission,make less vibration and noise.

Varies of connecting structure for power input and torque output meet different require-merits;the design of box outline and the set of foot hole with good versality is apt to many kinds of mounting.

The NMRV worm gOur company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on producStructural features The worm gear consists of three fundamental parts : housing, worm and wheel.t quality and runs marketing networks throughout the country. earbox is new generation of products by our factory on the basis of perfecting WJ series products with compromise of advanced technology both at home and abroad.It's apprearance adopts advanced square box structure.It's outer body is made of high quality aluminium alloy die casting into forming.It's small in volume,light weight,high in radiating efficiency,large in output torque,smooth in running and low noise.It's suitbale for all positions.

Method for model chosen

Please understand the following at first in order to delect the model of RV speed reducer properly.

- Loading condition

- Speed scope or ratio in application

- Working condition and environment

- Installation space

Company profile

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,If you’re looking for a 540 PTO shaft, 540 to 1000 PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no further. It’s important to replace PTO parts that are worn or cracking before you have a major breakdown that could be expensive and even dangerous. We have PTO drive shafts as well as essential shield parts for your safety. Our Eurocardan parts include a range of types of clutches to improve the operation of your power take-off system. PTO shafts and accessories are an important part of the more than 26,000 items we carry for farm, shop, home and garden.Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for danger in times of peace, unremitting......

Application area

Certifications

Detailed Images

Packing & Delivery

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZJ China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application...as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

china Trusted and Audited Suppliers supplier K series KF97 helical-bevel speed reducer gearbox

Owing to our broad solution assortment and rich ordeals in this market, we are confident to provide our clients adaptable and diversified solutions.

Overview

Rapid Details

- Relevant Industries:

-

Manufacturing Plant

- Pole:

-

single stage two phase three phase 4 phase

- Ratio:

-

seven.96-16978

- Housing Substance:

-

Solid Iron

- Content:

-

20CrMnTi

- Working temperature:

-

-forty~45℃

- Application:

-

K collection helical-bevel speed reducer

- Procedure:

-

Carburizing, Nitriding , Grinding

- Effectiveness:

-

ninety two%~96%

- Mounting Situation:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Purple

Packaging & Shipping

-

Lead Time

: -

Quantity(Bags) 1 - thirty >30 Est. Time(days) twenty To be negotiated

Online Customization

Solution Description

Expert MANUFACTURE

—— Since 1995

K series Bevel Helical Gear Motor Speed Reducer

Challenging Tooth Sureface Equipment

Proper Angle telescope worm equipment pace Reducer

K67 KF67 SA67 Worm Equipment box motor Reducer ninety Diploma Gearbox

Chinese gearbox velocity reducer —— Developed on the basis of modular blended method,

the equipment reducer have considerable combos of motor,mounting situation and composition initiatives,

the classifying class of transmission ratio is detailed,which is ideal for distinct doing work predicament and recognize mechatronics.

Specification

Chinese Large Performance mixer Gearbox Appropriate Angle Helical worm equipment Motor Reducer S67 SF67 SA67 SAF47 Helical Worm Gear Pace Reducer ninety Diploma Gear box:

| S Series Specification | |||||||

| Dimensions | 37 | 47 | fifty seven | 67 | 77 | 87 | 97 |

| Structure | F FA FF FAF FAZ | ||||||

| Input power score(kw) |

.18-.75 | .18-one.five | .18-3. | .25-five.five | .55-seven.5 | .75-15 | 1.five-22 |

| Ratio | ten.27-1265.71 | eleven.forty six-244.seventy four | ten.seventy eight-196.21 | eleven.55-227.twenty | nine.ninety six-241.09 | eleven.83-223.26 | 12.75-230.48 |

| Permissible torque N.m |

90 | one hundred seventy | 300 | 520 | 1270 | 2280 | 4000 |

Model selection:

Carefully utilizing the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft pace

Torque calculation: Torque calculation is quite crucial for the life of reducer, and spend attention to no matter whether the optimum torque price (TP) of acceleration exceeds the maximum load torque of the reducer.

The relevant energy is typically the relevant energy of the servo types on the market place, the applicability of the reducer is very higher, the functioning coefficient can be preserved earlier mentioned 1.2, but the choice can also be primarily based on their personal wants to determine. Appropriate Angle Helical worm gear Motor Reducer S67 SF67 SA67 SAF47 Helical Worm Gear Velocity Reducer 90 Diploma Equipment box.

Undertaking Cases

Business Data

Establishedin 1995 , HangZhou Ever-Electricity Machinery is a expert manufacturer and exporter that is concerned with the design and style, development and generation of Gearbox Velocity Reducer. We are situated in HangZhouof ZheJiang Province, with convenient transportation accessibility. With our own brand“EPG”, all of our products comply with global good quality expectations and are greatly appreciated in a selection of distinct markets during the globe.

Our business possesses comprehensive machining center, lathe, equipment shaping device, gear milling machine, equipment grinding equipment and assembling traces. Our well-equipped facilities and superb good quality control during all levels of creation allows us to promise whole consumer gratification.

Apart from, In 2005,we attained ISO9001 certification. As a result of our high quality products and fantastic customer provider, we have received aglobal product sales networkreaching South The usa, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With prosperous export experience, highqualityproducts, aggressive charges, very good services and in-time delivery, we particular that we can meet all of your need and exceed your expectations. Our attribute is brilliant with new cooperative associations with firms from all above the entire world. We look forward to talking with you tofuturediscuss how we can be of support to you.

Technological innovation

Gear Motor Velocity Reducer is a mechanical transmission in numerous fields of the countrywide economic system. The product categories protected by the business consist of all kinds of gear reducer, planetary gear reducer and worm gearbox, as effectively as different special transmission devices these kinds of as speed rising gadget, pace control Units, such as various types of flexible transmission gadgets, such as compound transmission. Merchandise and services in the field of metallurgy, nonferrous metals, coal, constructing components, ships, h2o conservancy, electrical energy, development machinery and petrochemical industries.

Chinese gearbox industry has a historical past of nearly forty several years. In all fields of countrywide economic climate and national defense market, gearbox goods have a broad range of applications. Meals mild market, electrical equipment, development equipment, metallurgy machinery, cement equipment, environmental security machinery, digital appliances, road design equipment, drinking water conservancy machinery, chemical machinery, mining machinery, conveyor equipment, developing resources equipment, rubber equipment, petroleum equipment and other industries have robust demand from customers of Reducer products. Chinese Large Effectiveness mixer Gearbox S67 Worm Gear Speed Reducer with electric powered motor Appropriate Angle Helical worm gear Motor Reducer S67 SF67 SA67 SAF47 Helical Worm Equipment Pace Reducer ninety Diploma Equipment box.K series helical-bevel pace reducer

Packaging & Shipping and delivery

Primary Goods

Chinese electric motor gearbox reducer is broadly employed in mining equipment, chemical business,metal metallurgy, light-weight industry,environmental safety, paper generating, printing, lifting transportation, food sector and so on.

Our Major Products:

- R serieshelical equipment motor gearbox reducer

- K seriesspiral bevel equipment reducer

- F seriesparallel shadt gear motor reducer

- S seriesworm gear reducer motor gearbox

- NGW, P seriesplanetary gear box reducer

- H B seriesgearbox

- Z (ZDY, ZLY, ZSY, and ZFY) serialhard tooth surface cylindrical gearbox

- D (DBY and DCY) serialhard tooth surface cone gearbox

- X B Seirescycloidal gearbox reducer

- ZLYJExtruder Gearbox,and so forth.

Meanwhile, map sample processing enterprise can be undertaken.

FAQ

1.Q:Are you the manufacturing unit or trading organization?

A:We are the professional Factory with 22 many years of knowledge.

two.Q:Can you customise according to our demands?

A:Sure, we can style nonstandard items according to customer's drawing and sample.

three.Q:How extended is the delivery date?

A:ten-20 operating days.

four.Q:In which is your manufacturing facility?

A:We are in HangZhou of ZheJiang Province, you can get below by higher pace train or fly to Jinan.

Welcome to go to us!

worm China gear reducer malaysia nmrv050 speed reducer gearbox worm gear supplier - Supplier Manufacturer wholesaler Factory

For more details.: Cellular/Whatpp: +8613083988828

EPG has set up a full set of good quality management program which is supplied with innovative inspection and examination tools. The company covering 88,000 square meters, has superior tools and robust technical strength, this kind of as the numerical handle equipment equipment and machining facilities, CAD/CAM system, industrial robotic etc.

Overview

Rapid Details

- Applicable Industries:

-

Manufacturing Plant

- Product NO:

-

SYF

- Colour:

-

Buyer Ask for

- Ratio:

-

five-a hundred

- Material:

-

Aluminium Alloy

- Warranty:

-

1-2 Several years

- Certification:

-

ISO9001

- Bearing:

-

NSK Bearing

- Warmth treatment method:

-

fifty eight-62 HRC

- Output Form:

-

Hollow Sahft Output

- Equipment substance:

-

45# Forged Metal

Packaging & Supply

-

Lead Time

: -

Quantity(Bags) 1 - 2 3 - ten >10 Est. Time(days) 3 8 To be negotiated

On-line Customization

Mounting Dimension

The items are broadly used in the creating equipments of all kinds of industries inside of and exterior China. They are the greatest selections for nowadays modern day facilities of mechanical minimizing drive control to realize massive twisting distance, huge gear ratio, tiny sound, large effectiveness and steadiness.

|

Model: |

NMRV025, 030, 040, 050, 063, 075, 090, one hundred ten, one hundred thirty, a hundred and fifty |

|

Ratio: |

1:5,7.five,ten,fifteen,twenty,25,thirty,40,fifty,60,80,100 |

|

Shade: |

Blue, Silver Or On Client Request |

|

Sounds: |

low noise (<50DB) |

|

Advantage: |

Productive and protected working |

|

Material: |

Housing: Die-Forged Aluminum Alloy |

|

Worm Equipment-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, surface area harness is 56-62HRC |

|

|

Shaft-chromium steel-forty five# |

|

|

Packing: |

Carton and Wood Scenario |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certificate: |

ISO9001,CE,3C,OEM |

|

Warranty: |

12 months |

|

Enter Power: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, one.1kw, 1.5kw, two.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Equipment: Foodstuff Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Artificial & Mineral |

Item Deseription

Single Phase Worm Gear Reducer.

The gearbox which design is twenty five~90 manufactured of Aluminum alloy die-casting box,very good looking in visual appeal,compact in framework,rust proofing on surface area and modest volume to save mounting space.

The gearbox product of 110~one hundred fifty is manufactured of forged iron which casted with Aluminum mould.It`s good looking and reliable, and can be used via the placing of multi-azimuth.

Very good radiating characterstic leads safe and trustworthiness,and higher performance for utilizing.

The strong capability of loading make certain secure transmission,make less vibration and sound.

Varies of connecting framework for energy enter and torque output meet diverse demand-meritsthe design of box outline and the established of foot hole with great versality is apt to a lot of types of mounting.

The NMRV worm gearbox is new generation of merchandise by our factory on the basis of perfecting WJ collection products with compromise of sophisticated engineering equally at property and abroad.It is apprearance adopts superior square box structure.It really is outer human body is produced of substantial good quality aluminium alloy die casting into forming.It really is tiny in quantity,light-weight excess weight,higher in radiating performance,big in output torque,smooth in operating and lower sounds.It's suitbale for all positions.

Technique for product decided on

Remember to comprehend the pursuing at 1st in get to delect the model of RV speed gearbox correctly.

- Loading issue

- Velocity scope or ratio in application

- Functioning situation and setting

- Set up area

Business profile

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Gear Co., Ltd.is a reward enterprise integrating improvement, style, manufacturing and product sales,Main promoting merchandise include gearbox motor,water pump,design equipment and areas,bearings,components and electrical tools,plastic items,Labour protection equipment.Our firm always follow the procedure principle which contains individuals-oriented, innovation as the soul,be ready for hazard in occasions of peace, unremitting......

Application spot

Certifications

In depth Images

Packing & Shipping

|

Packaging |

||

|

Size |

five hundred (L) * five hundred (W) * four hundred (D) |

|

|

Bodyweight |

1.two T |

|

|

Packaging Particulars |

The regular package deal is picket box(Measurement: L*W*H). If export to european nations around the world,the wooden box will be fumigated.If container is also tigher,we will use pe movie for packing or pack it in accordance to customers particular ask for. |

|

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Fat |

one.two T |

|

|

Packaging Particulars |

The normal package is wood box(Dimension: L*W*H). If export to european nations around the world,the wooden box will be fumigated.If container is also tigher,we will use pe film for packing or pack it in accordance to clients particular request. |

|

FAQ

Q1: Are you investing organization or company ?

A: We are a company in Jiangsu China.welcome to our manufacturing facility to have a check out.

Q2: How we decide on types and requirements?

A:You can e-mail us the collection name & code (for example: WJ collection worm gearbox) as nicely as need particulars, this kind of as motor electrical power, output pace or ratio, support issue or your application...as a lot data as achievable. If you can provide some images or drawings, it is greater.

Q3: How is your price? Can you offer you any price cut?

A: We will give the ideal cost we can base on your needs and the portions.

This autumn: How extended ought to I hold out for the opinions following I ship the enquiry?

A: Within 12 hours.

Q5: What is your merchandise guarantee time period?

A:We supply one particular calendar year guarantee considering that the vessel departure date remaining China.

Q6: What industries are your gearboxes currently being utilised?

A:Our gearboxes are broadly applied to metallurgical equipment, mining gear, automation gear, food machinery, packaging gear, tobacco gear and so on.

EPG - one of the biggest transmission factory in China, main items: worm geared motors, agricultrual gearbox, planetary equipment push, helical,screw, beve gears and spare parts and agricultural elements manunfacuter in ChinaFor far more information.: Mobile/Whatpp: +8613083988828