parallel shaft gearmotor helical inline gearmotor motoreductor gearmotor reductor gear reducer with reducer backstop

F series gear reducer is 1 kind of parallel shaft helical gear reducer , which consist of 2 or 3 stageshelical gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,theprocess of carburizing and quenching, grinding ,which give it follow characters :Stable transmission ,low noiseand temperature ,high loading ,long working lift . Wide application ,specialize in Metallurgy ,Sewage treatment,Chemical Industry , Pharmacy ,Agriculture equipment and Oil industry

Specifications:1) Output speed: 0.6~1,571r/min2) Output torque: up to 21700N.m3) Motor power: 0.12~200kW4) Mounted form: foot-mounted and flange-mounted mounting

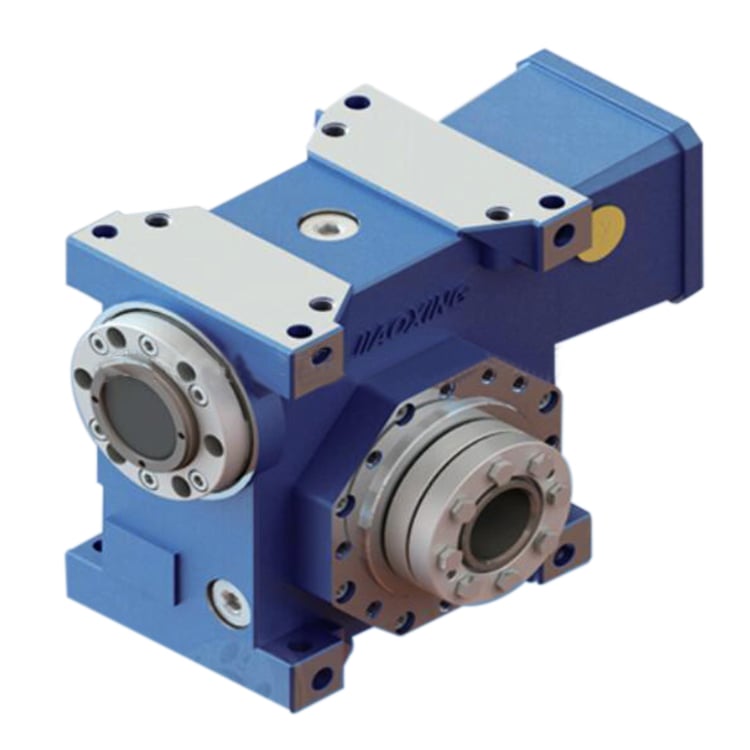

Product NameSLK Series Rigid Tooth helical bevel reducer Gear Material20CrMnTi Case MaterialHT250Shaft Material 20CrMnTiGear ProcessingGrinding finish by HOFLER Grinding MachinesColor CustomizedNoise Test65~70dBEfficiency94%~98% (depends on the transmission stage) Lubricating oilShell Omala synthetic oil or mineral oil , or similar brand Heat treatmenttempering, cementiting, quenching,etc.Brand of bearingsC&U bearing, ZWZ,LYC, HRB, SKF,NSK and so onBrand of oil sealNAK or other brandTemp. rise (MAX)40 °Temp. rise (Oil)(MAX)50 °Vibration≤20µ Original Advance mb170 marine gearbox in China m

Certifications

Packaging & Shipping

Packing Details: Standard carton/Pallet/Standard wooden case

Delivery Details : 7-20 working days upon payment

Company InformationAbout us

Established in 1985, CZPT TRANSMISSION MACHINERY CO., LTD is a high and new technology enterprise engaging in research, develop and manufacture for reducer & speed variator, 1 of the director member of China Reducer Association of China General Machinery.

It covers more than 40,000 square meters, has more than 400 staff , 20% of whom are technicians, equipped with more than 300 sets the most advanced accurate numerical control equipment, including German HOFLER forming gear grinding machine to improve quality.

set up more than 30 national sales branches to serve our customers in time and thoroughly.

Our products also exported to more than 30 countries main in Europe, Asia America, and Africa, with high reputation.

Trade Shows

Related Product

Main product list: 16 series including SLR/SLS/SLK/SLF series hard tooth flank gear reducer , SLRC series aluminium case helical gear reducers,SLHSLB series high power speed reducer, SLP series planetary speed reducer, X/B series cycloidal reducer, SLXG series shaft-mounted gear box, SLSWL series worm screw jack, SLT series helical cone gear box, altogether more than 10,000 ratios, various specification make us at the head of domestic transmission industry, widely serve the mechanical transmission field of light & heavy industry such as: beer & High precision high torque CZPT RV-E cycloidal gearbox reducer for robot joints beverage, mining machine, food packing, textile printing, rubber & plastic material, petrochemical industry, jack-up transportation, pharmacy & process hides, environmental protection equipment.

FAQ1.Payment Term: TT, L/C

2.Delivery time: about 30 days from receive payment.

3.We accept customized products as per your special requirement.

4.Xihu (West Lake) Dis.lines for the Selection:Usually we can select 1 machine which is suitable for you with some informations from you,such as ratio/motor speed/mounting dimension/ out torque etc.

5.If the minimum order amount is in excess of $10000, there are preferential.

Q1: What information should I tell you to confirm the product?

A:Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I don't know which 1 I need?

A:Dont worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q3: What is your product warranty period?

A:We offer 1 year warranty since the vessel departure date left China.

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q7: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, Heavy duty V belt pulley sheaves machine V pulley mining machinery pulleys pls feel free to contact us as below:

Contact us

How to Choose the Right Worm Shaft

You might be curious to know how to choose the right Worm Shaft. In this article, you will learn about worm modules with the same pitch diameter, Double-thread worm gears, and Self-locking worm drive. Once you have chosen the proper Worm Shaft, you will find it easier to use the equipment in your home. There are many advantages to selecting the right Worm Shaft. Read on to learn more.

Concave shape

The concave shape of a worm's shaft is an important characteristic for the design of a worm gearing. Worm gearings can be found in a wide range of shapes, and the basic profile parameters are available in professional and firm literature. These parameters are used in geometry calculations, and a selection of the right worm gearing for a particular application can be based on these requirements.

The thread profile of a worm is defined by the tangent to the axis of its main cylinder. The teeth are shaped in a straight line with a slightly concave shape along the sides. It resembles a helical gear, and the profile of the worm itself is straight. This type of gearing is often used when the number of teeth is greater than a certain limit.

The geometry of a worm gear depends on the type and manufacturer. In the earliest days, worms were made similar to simple screw threads, and could be chased on a lathe. During this time, the worm was often made with straight-sided tools to produce threads in the acme plane. Later, grinding techniques improved the thread finish and reduced distortions resulting from hardening.

When a worm gearing has multiple teeth, the pitch angle is a key parameter. A greater pitch angle increases efficiency. If you want to increase the pitch angle without increasing the number of teeth, you can replace a worm pair with a different number of thread starts. The helix angle must increase while the center distance remains constant. A higher pitch angle, however, is almost never used for power transmissions.

The minimum number of gear teeth depends on the angle of pressure at zero gearing correction. The diameter of the worm is d1, and is based on a known module value, mx or mn. Generally, larger values of m are assigned to larger modules. And a smaller number of teeth is called a low pitch angle. In case of a low pitch angle, spiral gearing is used. The pitch angle of the worm gear is smaller than 10 degrees.

Multiple-thread worms

Multi-thread worms can be divided into sets of one, two, or four threads. The ratio is determined by the number of threads on each set and the number of teeth on the apparatus. The most common worm thread counts are 1,2,4, and 6. To find out how many threads you have, count the start and end of each thread and divide by two. Using this method, you will get the correct thread count every time.

The tangent plane of a worm's pitch profile changes as the worm moves lengthwise along the thread. The lead angle is greatest at the throat, and decreases on both sides. The curvature radius r" varies proportionally with the worm's radius, or pitch angle at the considered point. Hence, the worm leads angle, r, is increased with decreased inclination and decreases with increasing inclination.

Multi-thread worms are characterized by a constant leverage between the gear surface and the worm threads. The ratio of worm-tooth surfaces to the worm's length varies, which enables the wormgear to be adjusted in the same direction. To optimize the gear contact between the worm and gear, the tangent relationship between the two surfaces is optimal.

The efficiency of worm gear drives is largely dependent on the helix angle of the worm. Multiple thread worms can improve the efficiency of the worm gear drive by as much as 25 to 50% compared to single-thread worms. Worm gears are made of bronze, which reduces friction and heat on the worm's teeth. A specialized machine can cut the worm gears for maximum efficiency.

Double-thread worm gears

In many different applications, worm gears are used to drive a worm wheel. These gears are unique in that the worm cannot be reversed by the power applied to the worm wheel. Because of their self-locking properties, they can be used to prevent reversing motion, although this is not a dependable function. Applications for worm gears include hoisting equipment, elevators, chain blocks, fishing reels, and automotive power steering. Because of their compact size, these gears are often used in applications with limited space.

Worm sets typically exhibit more wear than other types of gears, and this means that they require more limited contact patterns in new parts. Worm wheel teeth are concave, making it difficult to measure tooth thickness with pins, balls, and gear tooth calipers. To measure tooth thickness, however, you can measure backlash, a measurement of the spacing between teeth in a gear. Backlash can vary from one worm gear to another, so it is important to check the backlash at several points. If the backlash is different in two places, this indicates that the teeth may have different spacing.

Single-thread worm gears provide high speed reduction but lower efficiency. A multi-thread worm gear can provide high efficiency and high speed, but this comes with a trade-off in terms of horsepower. However, there are many other applications for worm gears. In addition to heavy-duty applications, they are often used in light-duty gearboxes for a variety of functions. When used in conjunction with double-thread worms, they allow for a substantial speed reduction in one step.

Stainless-steel worm gears can be used in damp environments. The worm gear is not susceptible to rust and is ideal for wet and damp environments. The worm wheel's smooth surfaces make cleaning them easy. However, they do require lubricants. The most common lubricant for worm gears is mineral oil. This lubricant is designed to protect the worm drive.

Self-locking worm drive

A self-locking worm drive prevents the platform from moving backward when the motor stops. A dynamic self-locking worm drive is also possible but does not include a holding brake. This type of self-locking worm drive is not susceptible to vibrations, but may rattle if released. In addition, it may require an additional brake to keep the platform from moving. A positive brake may be necessary for safety.

A self-locking worm drive does not allow for the interchangeability of the driven and driving gears. This is unlike spur gear trains that allow both to interchange positions. In a self-locking worm drive, the driving gear is always engaged and the driven gear remains stationary. The drive mechanism locks automatically when the worm is operated in the wrong manner. Several sources of information on self-locking worm gears include the Machinery's Handbook.

A self-locking worm drive is not difficult to build and has a great mechanical advantage. In fact, the output of a self-locking worm drive cannot be backdriven by the input shaft. DIYers can build a self-locking worm drive by modifying threaded rods and off-the-shelf gears. However, it is easier to make a ratchet and pawl mechanism, and is significantly less expensive. However, it is important to understand that you can only drive one worm at a time.

Another advantage of a self-locking worm drive is the fact that it is not possible to interchange the input and output shafts. This is a major benefit of using such a mechanism, as you can achieve high gear reduction without increasing the size of the gear box. If you're thinking about buying a self-locking worm gear for a specific application, consider the following tips to make the right choice.

An enveloping worm gear set is best for applications requiring high accuracy and efficiency, and minimum backlash. Its teeth are shaped differently, and the worm's threads are modified to increase surface contact. They are more expensive to manufacture than their single-start counterparts, but this type is best for applications where accuracy is crucial. The worm drive is also a great option for heavy trucks because of their large size and high-torque capacity.